AXI International's FPS products are programmable, fully automated, fuel maintenance systems that remove water, sludge, and other contaminants from fuel storage tanks. Once installed, the FPS systems operate independently to ensure fuel reliability through routine fuel filtration. These compact fuel maintenance systems are specifically designed for permanent installations indoors, as well as confined spaces, such as inside gen-set enclosures or engine rooms.

Available Systems:

Automated Filtration

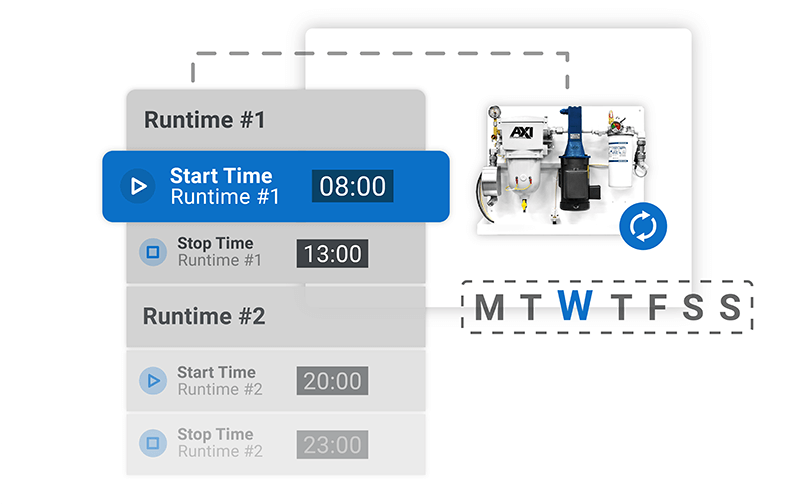

Schedule Fuel Polishing Runs

Keep your fuel free of contaminants through continual routine filtration. Set a weekly schedule that programs your FPS system to run automatically throughout the week. Simply select the days you want your system to filter the fuel and enter up three start and stop times per day.

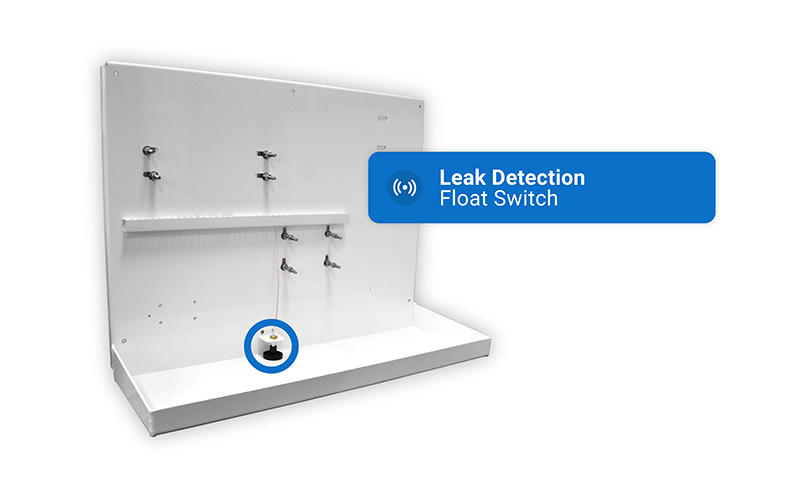

Compact Design

Aluminum Backplate Construction

Confidently mount your compact fuel polishing systems in engine rooms or generator enclosures. Prevent any unnecessary mess during routine maintenance with a built in drip tray. Be alerted in the unlikely case of a system leak with an included leak detection float sensor located in the system's drip tray.

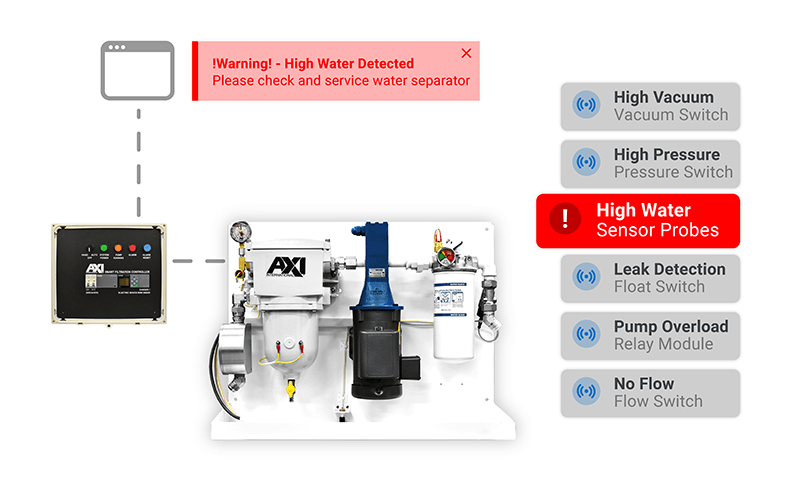

System Monitoring

Smart System Alarms & BMS Integration

Get realtime feedback on system statuses via the system's alarms and feedback modules. Know when it is time to change filters and be notified of system errors right as they occur. Integrate your FPS fuel maintenance system with your building management system (BMS) for remote monitoring of system statuses and remote system shutdown capabilities.

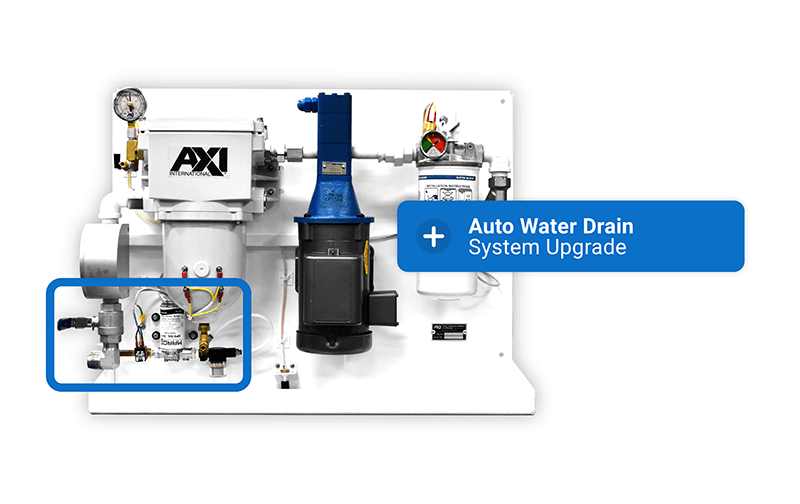

Upgrade Options

Enhanced System Features & Functions

Expand system capabilities, enhance user insight, and reduce routine maintenance with a robust set of system upgrade options. - See product pages for more details.

Engineering Services

Products

Resource Center

Information

All company names, logos, and brands are property of their respective owners. Use of these names, logos, and brands does not imply endorsement.

Copyright © 2024 AXI International | All Rights Reserved.

Copyright © 2024 AXI International | All Rights Reserved.