Leveraging flow simulations for optimal fuel polishing

Through our experience with flow simulations, our team has been able to analyze fuel tank designs to ensure fuel can be effectively maintained and kept free of contaminants. In the case of baffled or belly tanks, fuel maintenance systems may not be able to create efficient flow patterns to ensure most of the fuel reaches the system for filtration. As a result:

- Tanks experience areas of stagnation resulting in a regular presence of fuel contaminates

- Fuel quality can vary greatly throughout the tank

- Supplied engine/generators may continually experience the many problems associated with poor fuel quality

Improving fuel tank port placement for better system performance

AXI International’s simulation capabilities has allowed our team to visualize fuel temperature displacement as fuel is drawn from and returned to the tank to better identify port placement. Engines being fed hot fuel can cause a significant decrease in overall energy efficiency. This is why it is imperative, especially in smaller tank applications, to ensure proper port placement to prevent engines from running on hot fuel.

Optimizing tank designs and port placement with in-depth flow simulations

AXI International leverages computational fluid dynamic (CFD) simulations to influence crucial decisions to improve fuel tank design and port placement. The insights from our simulations can result in:

- Significant increases in the tank cleaning effectiveness of fuel maintenance systems

- Optimized baffle placement to mitigate areas of flow stagnation and maximize fuel flow during fuel filtration cycles

- Limiting the potential for hot fuel to be drawn into the engine thus preventing avoidable losses in efficiency

The Importance of Fuel Flow and Tank Design

Our simulations have shown fuel filtration systems fail to create sufficient flow velocity profiles within standard belly/base tank designs, leading to areas of stagnation. In these areas, contaminants can form and fall out of solution leading to functional problems within the facility. Premature filter clogging and injector damage are only some of the side effects of burning contaminated fuel. This is especially true in tier-4 engines where tolerances for contaminants are among the lowest.

The main constraints for fuel filtration within current base/belly tank designs involves the internal baffle structures. These baffles exist to provide structural support but tend to be restrictive in both design and placement due to a lack of feedback regarding fuel flow. AXI International aims to provide this crucial feedback allowing you to design fuel tanks that not only exhibit structural integrity but also strong flow velocity profiles for effective fuel maintenance.

Computational Fluid Dynamics Simulations

Computational Fluid Dynamics (CFD) is a way to analyze the physics of fluid flow computationally. CFD creates a mathematical model to look at the various flow properties of a design, including fluid velocity, vortex creation, and more. Utilizing a CFD analysis is oftentimes more practical than traditional research and development that involves physically building a tank, which can take great amounts of time and money to complete. This gives our clients the ability to simulate fluid flow without having to physically manufacture or alter existing tanks for testing.

AXI International’s Computational Fluid Dynamics (CFD) analysis offers insight on where improvements can be made during the tank design process. This powerful method allows us to test many unique designs and do a comparative analysis to determine the optimal design to move forward with. This ensures we keep a clean tank throughout its life, adding longevity to a site and providing the customer with an unparalleled peace of mind.

CFD Analysis in Application

With our CFD analysis, AXI International can provide guidance on the design of base and belly tanks by optimizing properties such as baffle placement, baffle design, and port placement for fuel filtration systems. This process ensures the tank receives a more complete cleaning coverage, effectively preventing the many consequences of contaminated fuel and poorly maintained tanks.

Currently, industry standards offer minimum recommendations such as “run your polisher 48 hours per week” or “install the pickup and return ports at opposite ends of the tank”. AXI International provides an avenue to move beyond these statements towards data driven decisions.

Multi-Point Flow Path Simulations

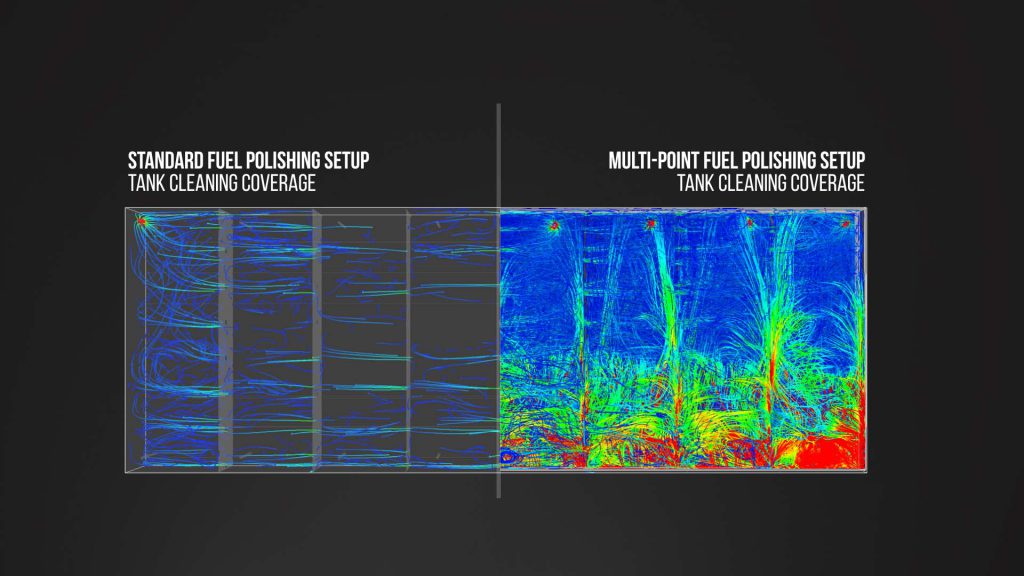

Using Computational Fluid Dynamics simulation software, our engineering team can run comparative studies to demonstrate the effectiveness of the Multi-Point Flow Path over traditional fuel maintenance installations.

Multi-Point Flow Path gives tank designers additional variables (port count and placement) to further optimize their tanks for maximum fuel flow. Utilizing the results from these comparative studies, these tanks can be proactively designed and manufactured with fuel flow velocity in mind.

Why Fuel Tank Analysis and Design

In a majority of industries, build time is a top priority, especially in the case of hyper-scale data centers. The nature of these applications makes any method to improve the efficiency of the construction phase valuable. This ensures manufacturers have the ability to meet the demand of their customer base as well as easily scale to capacity when needed. One solution that improves construction efficiency is the purchasing of “packaged” enclosed generator engines with fuel tanks pre-installed beneath them (belly/base tanks). These “packaged” units arrive on-site as modular backup power solutions that can be easily plugged in and ran.

With larger engines, the tanks beneath them can be of immense size and volume. This creates a very large surface area for phase separation of water and diesel to occur. The larger the interface between the separated water and diesel, the greater potential for microbial growth, contamination, and tank corrosion. In order to combat these threats, fuel maintenance systems are often installed to regularly filter out the water and other contaminants that develop in the tank. The effectiveness of these fuel maintenance systems can be greatly altered by the overall tank design and the ability of contamination to reach the system.

Oftentimes, these tanks are primarily designed with only structural integrity in mind. As a result, fuel flow becomes a costly afterthought as structurally-sound tanks are installed that even the most effective fuel filtration systems cannot maintain.

Engineering Services

Products

Resource Center

Information

Copyright © 2024 AXI International | All Rights Reserved.