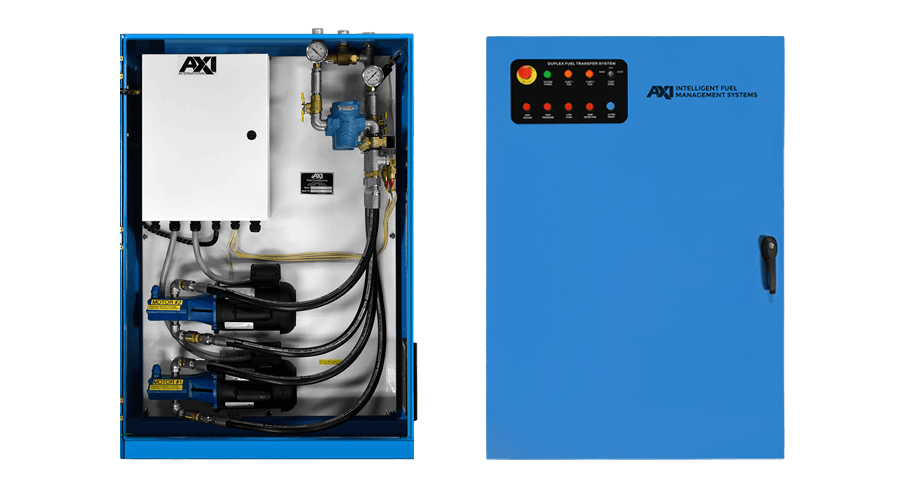

AXI’s FTS products are heavy-duty fuel transfer systems that move fuel between the requesting tank and demand source. These units ensure that mission critical systems have a ready and steady fuel supply to run at a moment’s notice. Depending on an individual’s requirements, these systems can be configured with a specific flow rate. Our options range from 2 to 16 GPM and also feature single or dual pumps for redundancy.

Fuel Transfer System Configurator:

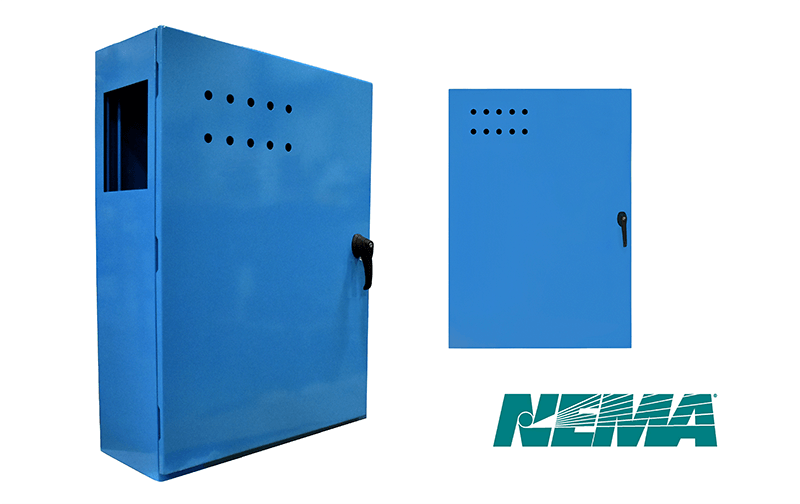

NEMA Rated Enclosure

Indoor & Outdoor Installations

Protect system components from the elements such as windblown dust and rain with NEMA 4 rated enclosures. Upgrade to NEMA 4X stainless steel for additional protection against corrosion. Prevent any unnecessary fuel spilling during system maintenance with a built-in spill basin. Be alerted in the unlikely case of a leak or spill with an included leak detection float sensor located in the system's drip basin.

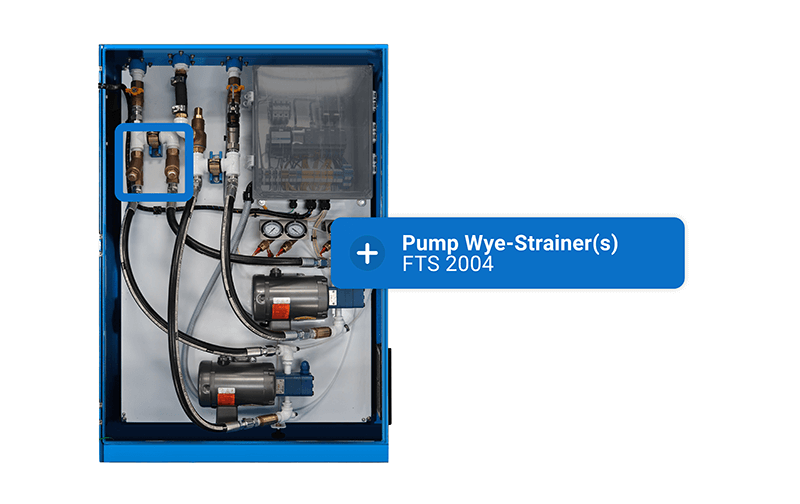

Advanced Pump Protection

Protect Pump Components

Prevent pump damage at high flow rates with pump suction basket strainers, catching large particulates during routine fuel transfers. Remove, clean, and reuse the stainless steel strainer baskets when particulate buildup occurs. For dual pump configurations, evenly distribute natural wear with the system's automated pump alternation feature, maintaining dual pump redundancy by alternating which pump is in use for each transfer procedure.

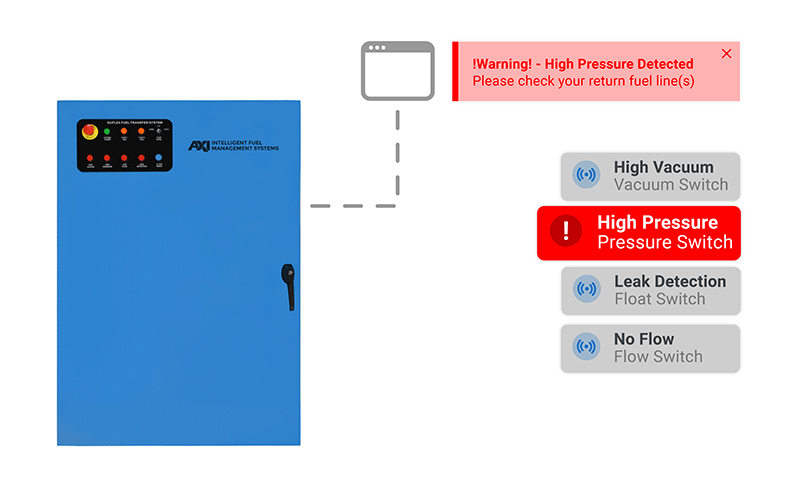

Smart System Monitoring

Smart System Alarms & BMS Integration

Get realtime feedback on system statuses through the system controller, indicators, and alarms for system power, pump operation, high pressure, no flow, leak detection, and high vacuum. Integrate your FTS fuel transfer system with your building management system (BMS) for remote monitoring of the transfer systems and remote shutdown capabilities.

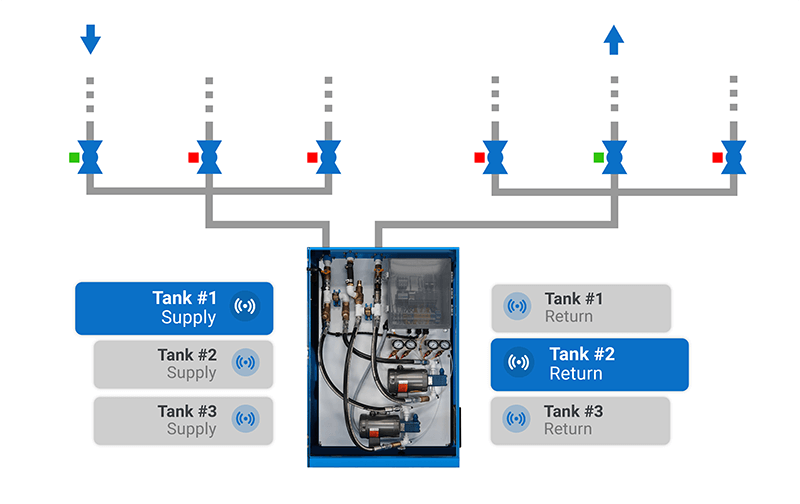

Multi-Tank Transferring

Transfer Fuel Between Multiple Storage Tanks

Pull fuel from and route to multiple source and destination tanks. Transfer fuel between tanks to achieve desired fuel levels in a particular tank. Monitor each tank's fuel levels via the system controller or established BMS Integration.

Engineering Services

Products

Resource Center

Information

All company names, logos, and brands are property of their respective owners. Use of these names, logos, and brands does not imply endorsement.

Copyright © 2024 AXI International | All Rights Reserved.

Copyright © 2024 AXI International | All Rights Reserved.