Addressing "Algae" in Diesel Fuel

There is nothing worse than opening your tank to discover your diesel fuel is contaminated with “algae“. If this fuel were ever to be used, it could wreak havoc on your fuel filters and consequentially your engine.

In acknowledging this, you may be asking yourself, "how do I get rid of this “algae” and prevent it for good?"

Luckily, we have some answers to those very questions. In this article, we’ll explain what the “algae” really is, where it comes from, common methods to combat it, and best practices to keep it at bay.

Understanding the "Algae" Problem

In order to properly address this fuel contamination issue, we must first understand what it is we are trying to combat and where it is that it comes from.

A Common Misnomer

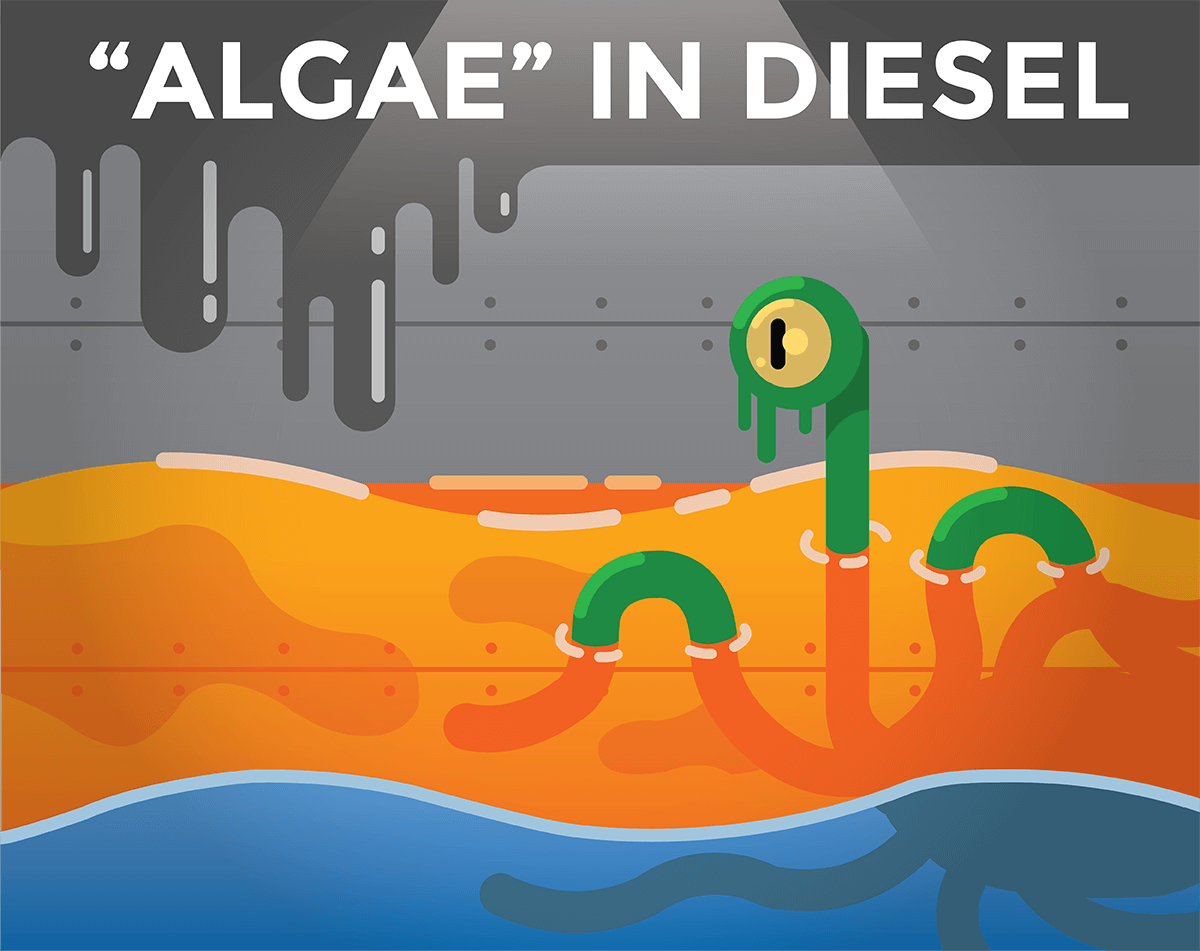

For decades, it has been a common misconception that the dark sludge forming in your fuel tank is actually “algae”. As a result, many still refer to it as such today. In reality, what you are actually witnessing is an over-proliferation of microbes in the fuel.

How do we know this?

For starters, your fuel tank is far too dark to harbor any known species of algae. These plant organisms need sufficient sunlight to survive.

On the other hand, it is well documented that there is no shortage of microbes dwelling in diesel fuel.

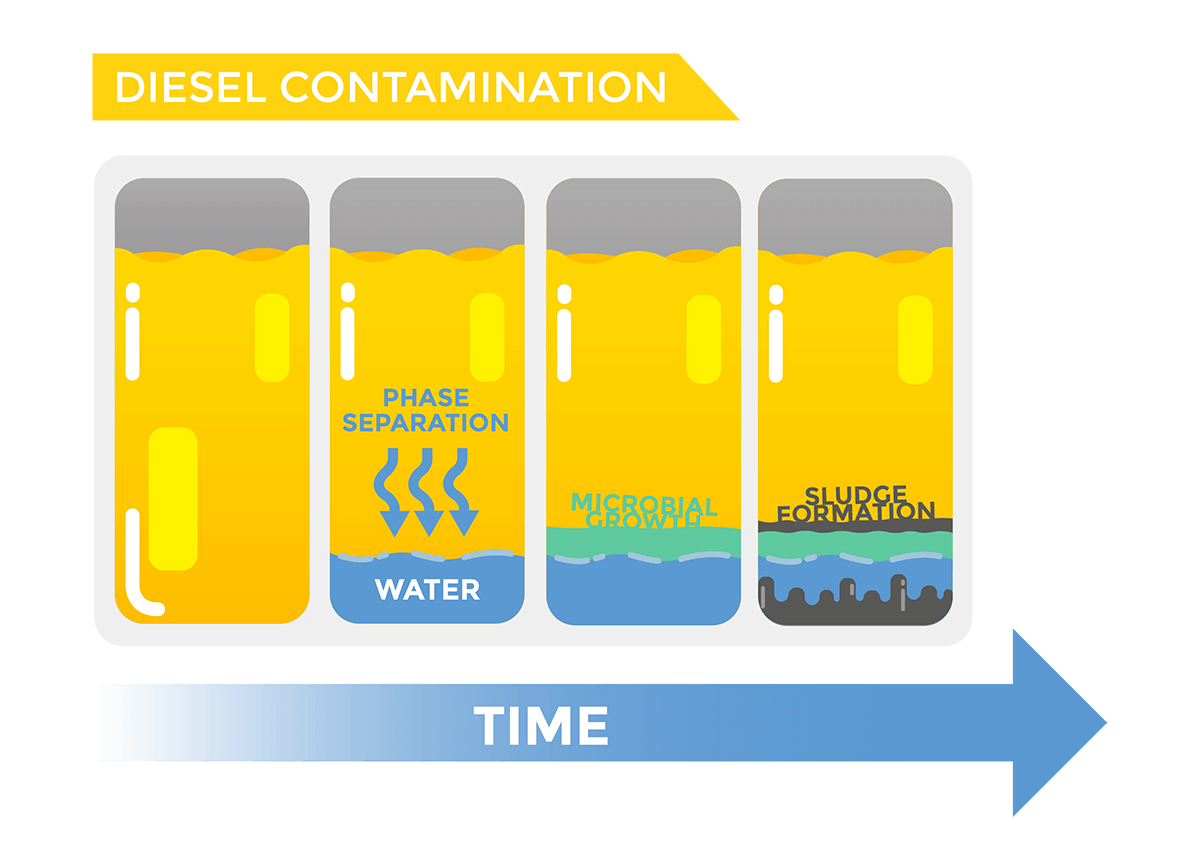

The problem of microbial contamination originates when water present in the diesel separates into a distinct layer below the fuel. This is commonly referred to as "phase separation". At this point in the process, you may begin to notice a dark layer forming in the fuel.

Another term often used to refer to this form of fuel contamination is the “diesel bug”.

The interface between the diesel fuel and the water creates the perfect breeding ground for various bacteria and fungi to thrive. The microbes will live and proliferate in the water while consuming the hydrocarbons from the diesel fuel above.

In time, the accumulation of microbes will form visible biomass (rag layer) between the water and diesel fuel. By-products and dead cells from the growing microbial communities also fall towards the bottom of the tank to create a viscous sludge.

The Effects of Microbial Growth

When churned up, the sludge by-product of microbial contamination can clog any engine filter with ease.

A clogged engine filter, especially one clogged at a time of importance, can cause serious problems.

For example, data centers relying on diesel generators for backup power may experience unexpected downtime due to clogged filters. This can result in costs of hundreds to tens of thousands of dollars a minute while unplanned maintenance is being carried out.

On a smaller scale, clogged filters on many marine vessels such as boats and yachts can often leave their operators stranded on the water.

“The diesel bug may start on a microscopic level, but it is clear it can lead to macroscopic consequences.”

Common Solutions for the "Diesel Bug"

There are a lot of opinions on how to best prevent “algae”/microbial proliferation in the fuel.

Some will push for the use of biocides which use hazardous chemicals to kill the microbes directly.

Others prefer fuel additives designed to prevent phase separation from happening.

At AXI International, we understand that neither of these solutions is perfect, but recognize they embody two valid methodologies for controlling microbial growth in diesel fuel.

You can either kill them directly or prevent the very conditions they need to thrive.

Biocides

Although initially effective, biocides are not the end-all solution to microbial growth and sludge formation.

Placing health, safety, and environmental concerns aside, frequent use of biocides can create resistant microbes that no longer die upon application.

This is due to the fact that it is nearly impossible to completely sterilize diesel fuel. As a result, the surviving microbes, through means of natural selection, will exhibit increasingly resistant traits that eventually render the biocides ineffective.

Best Practices for Microbial Contamination

If microbial growth has progressed to a point that it is noticeable, no treatment already mentioned will effectively remove or break up the sludge already formed in the tank.

Removing Microbial Sludge

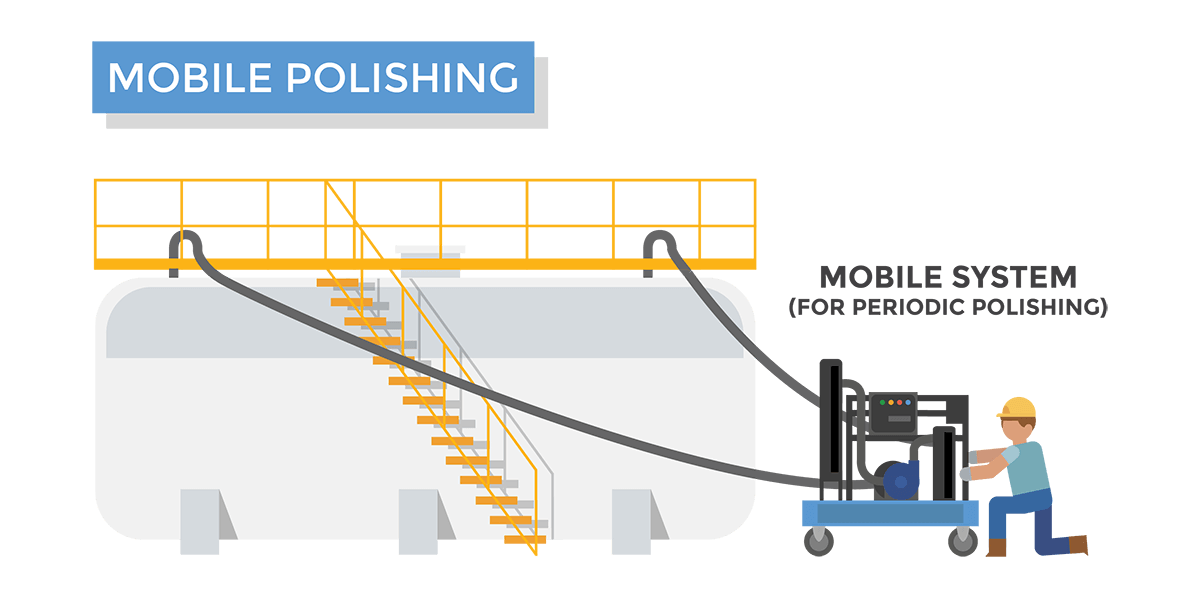

In order to remove sludge from the fuel, you will have to employ the use of a mobile fuel polishing service or system.

Mobile fuel polishing systems work by circulating the fuel out of the tank for filtration.

These systems are designed to effectively remove both large and small contaminants like particulates and sludge while also helping to prevent future microbial contamination through the removal of water.

Unfortunately, a single fuel polishing serve will not prevent microbial growth indefinitely. Water will find its way back into the tank through means of refueling and condensation formation. If fuel polishing is your preferred method of prevention, prepare to schedule multiple servicings throughout the year.

Preventing Microbial Growth

In some cases, fuel additives that pull water up into the fuel by means of an emulsifier can be an appropriate response to stifle microbial growth.

The additives work by addressing the problem at its source. Without phase-separated water, microbes cannot over-proliferate in the fuel.

In time, the emulsified water can exit the fuel tank as it is fed into the engine alongside the fuel and vaporized out the exhaust.

Preventative Solutions for Tier-4 Engines

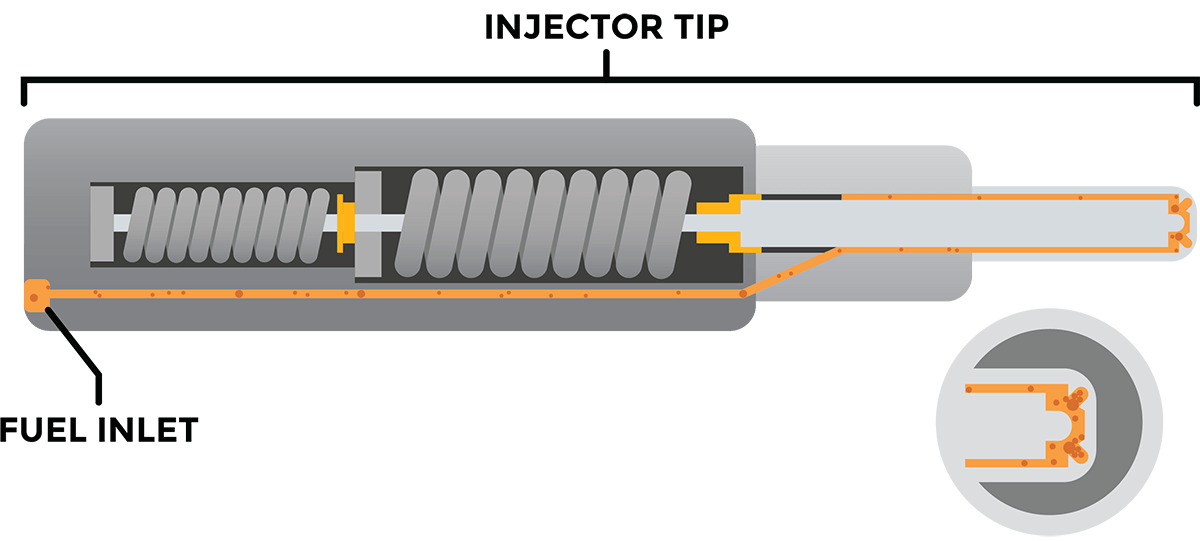

For applications involving Tier-4 compliant engines, water emulsifiers are not a recommended solution as they will only create additional problems. This is because Tier 4 engines have a High-Pressure Common Rail (HPCR) system that feeds the fuel into the combustion chamber at extremely high pressures with very little tolerance for anything other than the fuel itself.

Emulsified water, being much larger than the 2-4 micron injector openings, can cause abrasive wear and eventual failure of the injector tips. Due to this reality, Tier 4 engines require a much more technical solution.

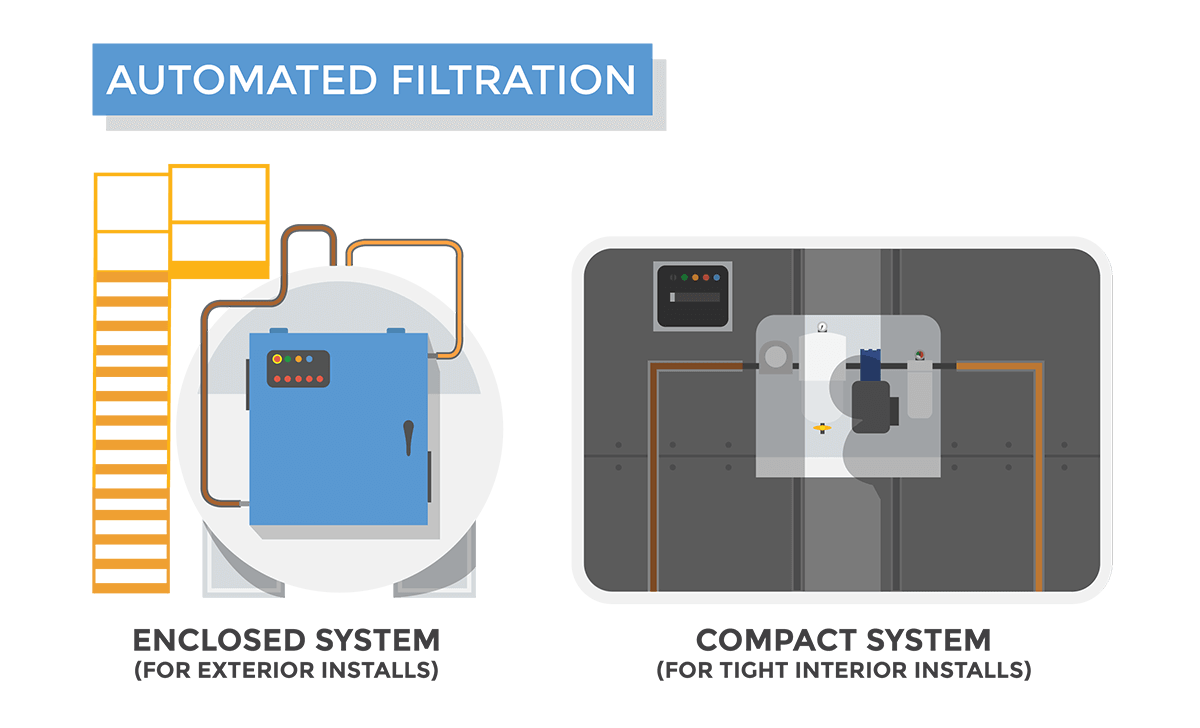

For Tier-4 engines, automated fuel maintenance systems are the best approach to prevent “algae”/microbial growth in diesel fuel. Fuel maintenance systems are permanent installations that work on a programmed schedule to regularly pull fuel from the tank to filter out contaminants.

Unlike fuel polishing systems, fuel maintenance systems are better at maintaining the fuel as opposed to reactively restoring it from a highly contaminated state.

By the same effect of fuel polishing systems, fuel maintenance systems prevent “algae“/microbial growth through the removal of water.

Fuel Filtration

Fuel Management

Stay Up to Date

Engineering Services

Products

Resource Center

Information

Copyright © 2024 AXI International | All Rights Reserved.