Corrosion Inhibitor

Over time, ethanol and gasohol become increasingly corrosive to metals commonly used in fuel distribution systems due to oxidative degradation. AFC's corrosion inhibitor stabilizes these products, protecting the tank and engine components from corrosion.

Features/Benefits

Increases the pH level in the fuel, preventing tank & engine corrosion caused by oxidative degradation.

Corrosion Inhibitor TESTING

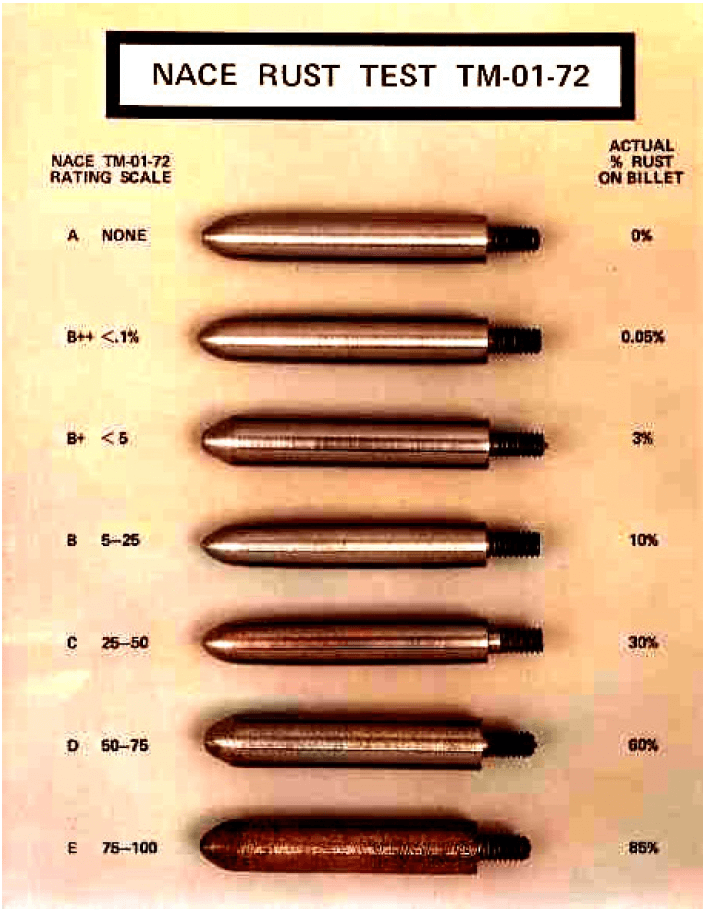

The following test was performed using the NACE Rust Test (TM-01-72), a modification of ASTM D665, which tests the corrosivity of a fuel and the effectiveness of additives at preventing corrosion. Testing was done with several samples of fuel, each dosed with different additive treat rates. Mild steel billets were suspended and agitated in these fuel samples for 30 minutes before 30 ml of deionized water was added to accelerate the corrosion process for an additional 3.5 hours.

- At the end of the test, the steel billets were removed and rinsed with acetone.

- Each billet was then rated on the NACE rating scale which provides a letter grade based on the percentage of rust observed on the billet.

- Generally, a rating of B++ or higher is desired to demonstrate the additive's ability to effectively control corrosion within fuel systems.

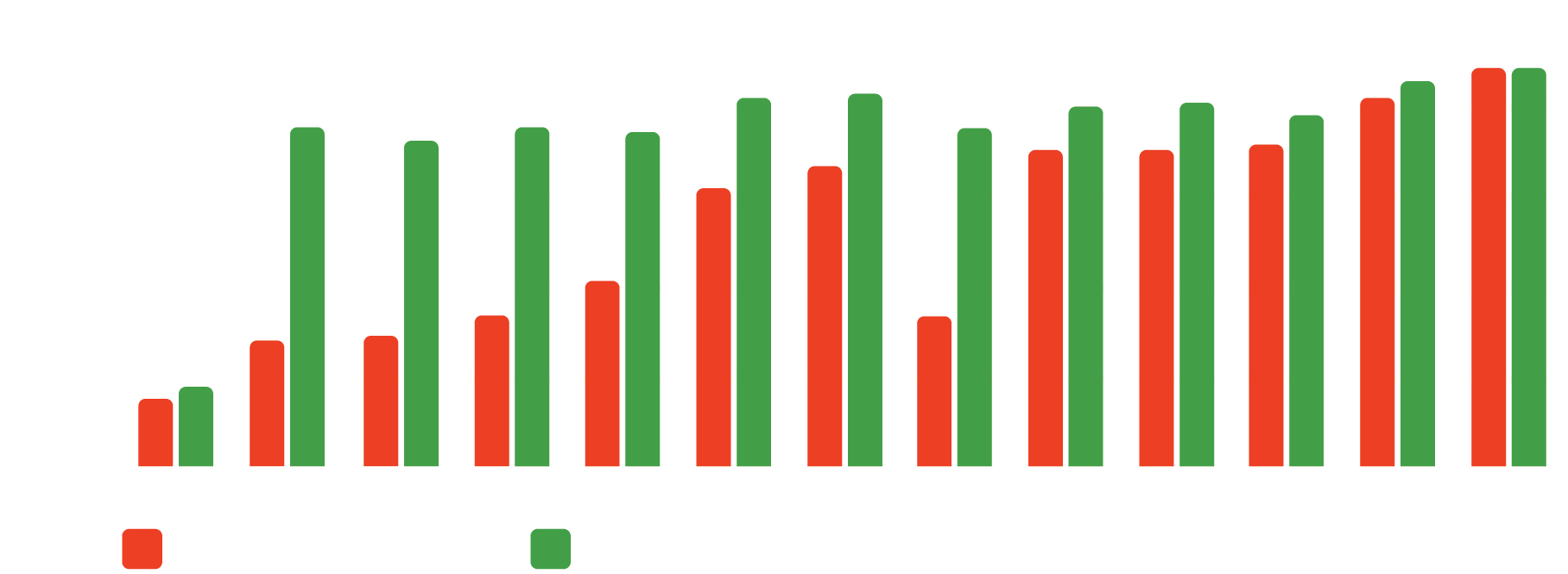

- The first chart demonstrates the corrosion inhibitor’s ability to protect against corrosion when exposed to finished gasohol during the NACE rust test.

- The percentage of rust is shown to be negatively correlated with the amount of corrosion inhibitor introduced into the gasohol solution.

- Only 90ppm of the corrosion inhibitor found in AFC is required to obtain an “A” NACE rating with ethanol that would otherwise score an “E”.

- The photograph depicts two carbon steel billets that were exposed to gasohol during the NACE rust test.

- The lower billet was exposed to untreated gasohol while the other was suspended in gasohol treated with 90 ppm of AFC’s corrosion inhibitor.

- A low pHe ethanol is correlated with poor performance in the NACE rust test due to increased acidity.

- The level of acidity in the fuel has been found to increase over time due to oxidative degradation.

- Testing has shown AFC's corrosion inhibitor will increase the pHe to ASTM specifications (between 6.5 and 9) in all ethanol with a base pHe greater than 2.5.

Engineering Services

Products

Resource Center

Information

All company names, logos, and brands are property of their respective owners. Use of these names, logos, and brands does not imply endorsement.

Copyright © 2024 AXI International | All Rights Reserved.

Copyright © 2024 AXI International | All Rights Reserved.