The Effects of Diesel Fuel Contamination

Fuel contamination can be felt in many ways, particularly in the mechanical operability of your engine or equipment. Some of these symptoms often go unnoticed, or ignored, while other symptoms can be severe and impossible to ignore.

Not only can these failures be extremely costly to repair, but these catastrophic failures can be dangerous, especially when they occur on the road or at high speeds.

Fortunately, many of these failures can be prevented through frequent fuel testing and the implementation of preventative solutions.

In this article, we will cover the symptoms, causes, testing, and solutions for all types of diesel fuel contamination.

Symptoms of Fuel Contamination

Don't Ignore Your Engine Check Light

Many people have been or have known someone that was in a situation where the “check engine” light comes on in their vehicle out of seemingly nowhere. Anxious at first, they tone down their driving to see if they can feel any difference in how the vehicle is running.

Strangely enough, it doesn’t feel any different than before- so they convince themselves it probably isn’t anything other than the car or truck being a bit “finicky”.

At first, a few days go by and then a few months. The light is still on and since the vehicle doesn’t feel to be running any different, it’s running just as often and hard as it normally would.

However, under the hood, components are not operating as designed and the continuous operation of worn parts is damaging the very systems that keep the vehicle running.

At this point, detrimental engine failure could be just a matter of time, turning a couple hundred dollar repair into one that could quickly cost thousands.

Clogged Fuel Filters

Frequently clogged fuel filters are oftentimes one of the first initial signs of possible diesel fuel contamination. The filter is designed to capture particles in your fuel before they pass into the engine and these pieces of matter can be made up of clumps of sludge, metallic particles, or other unwanted particulates.

If a fuel system is experiencing an atypical recurrence of fuel filter replacements, the problem’s root could lie in the quality of the fuel being supplied to the filter.

Heavily contaminated fuel would consistently provide particulates and other undesired materials that quickly clog filters, possibly leading to other issues in the fuel system.

This contamination could be stemming from either the fuel source itself or from the internal corrosion of the very fuel tank being used to fuel the engine.

Failing Fuel Pump

With frequent fuel filter clogging, fuel pump failure is often to follow. Because of the restriction caused by the clogged filters, the fuel pump could be working harder than designed to deliver fuel from the tank to the engine.

While a fuel pump is failing, the fuel pump will not be able to deliver a steady flow of fuel, interrupting the mechanical stroke and function of the engine. This can be especially noticeable under acceleration, where fuel demand is increased however the fuel pump is unable to deliver the fuel at the requested rate.

Symptoms of a failing fuel pump may include:

- Jerks or sputters at high speeds

- Power loss on acceleration

- Power loss while driving up a slope

- Power loss while towing

- Engine surging while acceleration is not engaged

- Engine will not fire

When a fuel pump is exerted to the point of failure, it is past the point of simple maintenance to get the engine running again. When a fuel pump fails, fuel line pressure is lost thus not being able to deliver any fuel for the engine to fire up. Downtime of equipment for major repair is expected at this point to get the fuel flowing properly again.

Partial Injector Failure

Unfortunately, partial functional failure of an engine will often go unnoticed until it is too late.

Engine inefficiencies are seldom felt by a user but can result in serious losses in operability and revenue.

A major reason for engine inefficiency stems from the partial failure of an engine’s fuel injection system, something not well understood by a majority of people.

Partial functional injector failure isn’t a failure point that is well-documented in many industries, leaving a lapse in the understanding of the symptoms that come with this kind of failure.

Although the equipment is still operable, partial functional failure of a fuel injection system is generally one that reduces engine efficiency or performance. The symptoms of such failures within an injection system may include the following:

- Low power from the engine

- Reduced engine RPM

- Increased fuel consumption

- Poor cycle times or low speed

- Smoke

- Lower gear selection

- Noise

- Poor starting

- Poor idle

Many of the symptoms mentioned above are difficult to diagnose without the proper tools and equipment, which makes needed repairs something that often falls behind.

By continuous operation of the equipment, the user is at risk of experiencing events of a catastrophic engine or component failure.

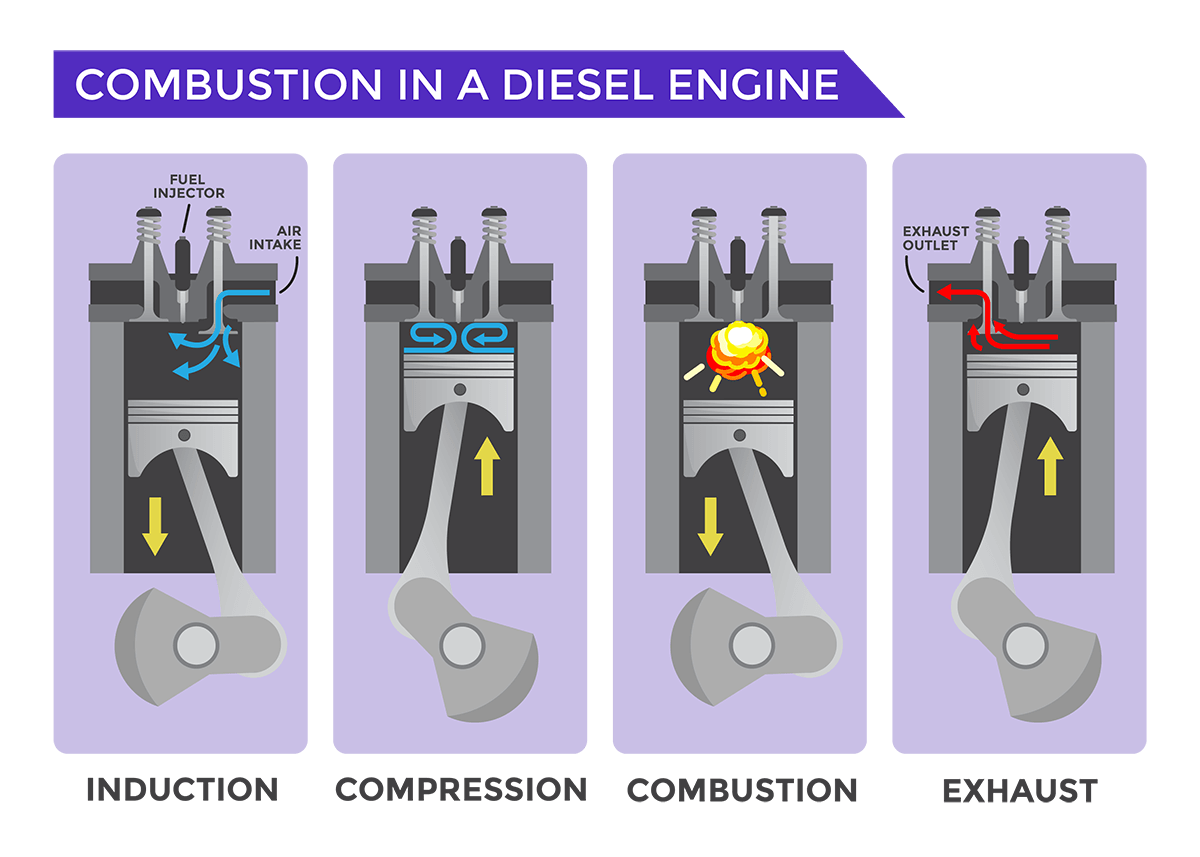

To understand the role fuel injection plays in the engine mechanically, one must understand the stroke cycle as referenced below.

During the power stroke, fuel is injected into the cylinder and ignites, creating the energy needed to transfer to the mechanical output that drives the vehicle or equipment.

Prior to manufacturing, diesel fuel injectors are designed with specific functional tolerances. If these injectors begin to fail or veer from the designed tolerances in any way, then the fuel spray trajectory within the combustion chamber is drastically affected.

Injectors can deviate from their tolerances through the introduction of contaminated fuel. Contaminated fuel can deteriorate and corrode the metal surfaces in injectors, with a higher likelihood after prolonged use of contaminated fuel.

Any number of these factors can alter the engineered functionality of a fuel injector, leading to a snowball effect of internal engine damage that could eventually progress into full functional engine failure.

Catastrophic Engine Injector Failure

When catastrophic engine injector failures are experienced, the engine fails to continue operation due to these sudden occurrences. Typically, these experienced events can only be restored through costly repairs that often result in prolonged equipment downtime.

Operations and equipment managers rely on proper equipment functionality to maintain revenue margins and business profitability. It is for these reasons that attention should be directed at managing, predicting, and preventing these failures from occurring through proper equipment maintenance and operation.

Equipment specialists and OEMs typically operate their equipment around recommended maintenance procedures that are designed to limit component failure and prolong equipment life.

It is common for OEMs to recommend these maintenance procedures to uphold warranties. Fuel injector replacements are a critical component to these OEM warranties, with recommendations often being at the engine’s half-life.

This is recommended because OEMs are aware that engines are not commonly supplied with quality fuel and are instead typically supplied with contaminated fuel that can damage injectors over time and jeopardize reliability.

Although equipment maintenance personnel are responsible for managing engine equipment and remediating potential issues, not all can be predicted and/or prevented. This is often the case with contaminated fuel, as operations managers are often limited in the fuel they can procure.

With the use of contaminated fuel, erosion of the injector valve seat is likely, resulting in a partial functional failure that will eventually lead to a full functional failure of the fuel injector valve.

The Failure Chain Reaction

- Contaminated fuel is sent through fuel injectors

- Fuel injector valve deterioration begins

- Fuel pressure through injector nozzle reduces

- Fuel volume through the injection system reduces

- Engine ECU increases fuel load to compensate

- Reduced fuel atomization

- Soot generation within the cylinder

- Emissions increased

- Experienced power loss

- Partial injection failure point

- Injector wear continues

- Fuel consumption increases

- Visible and audible signs of engine distress

- Full injection failure

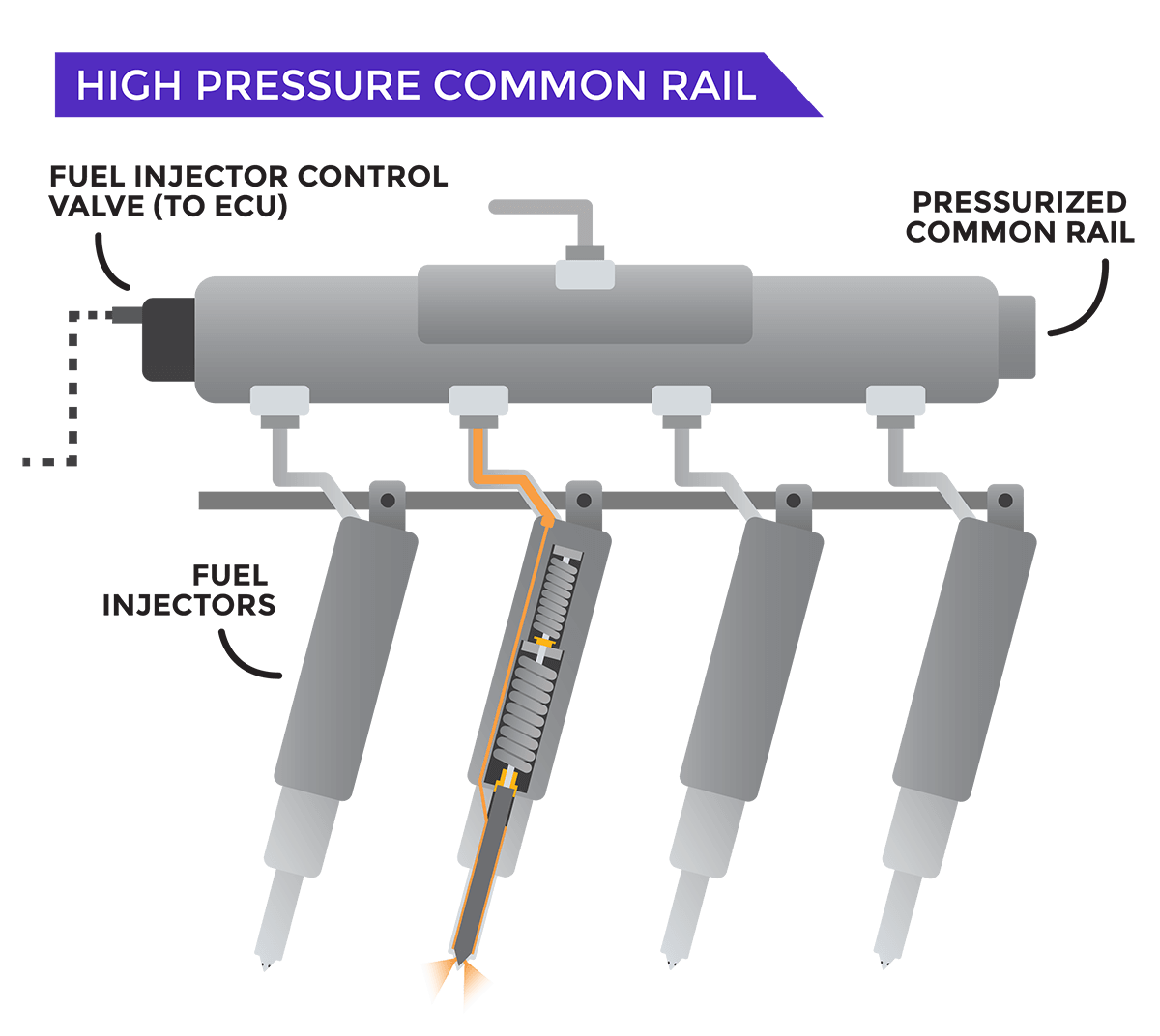

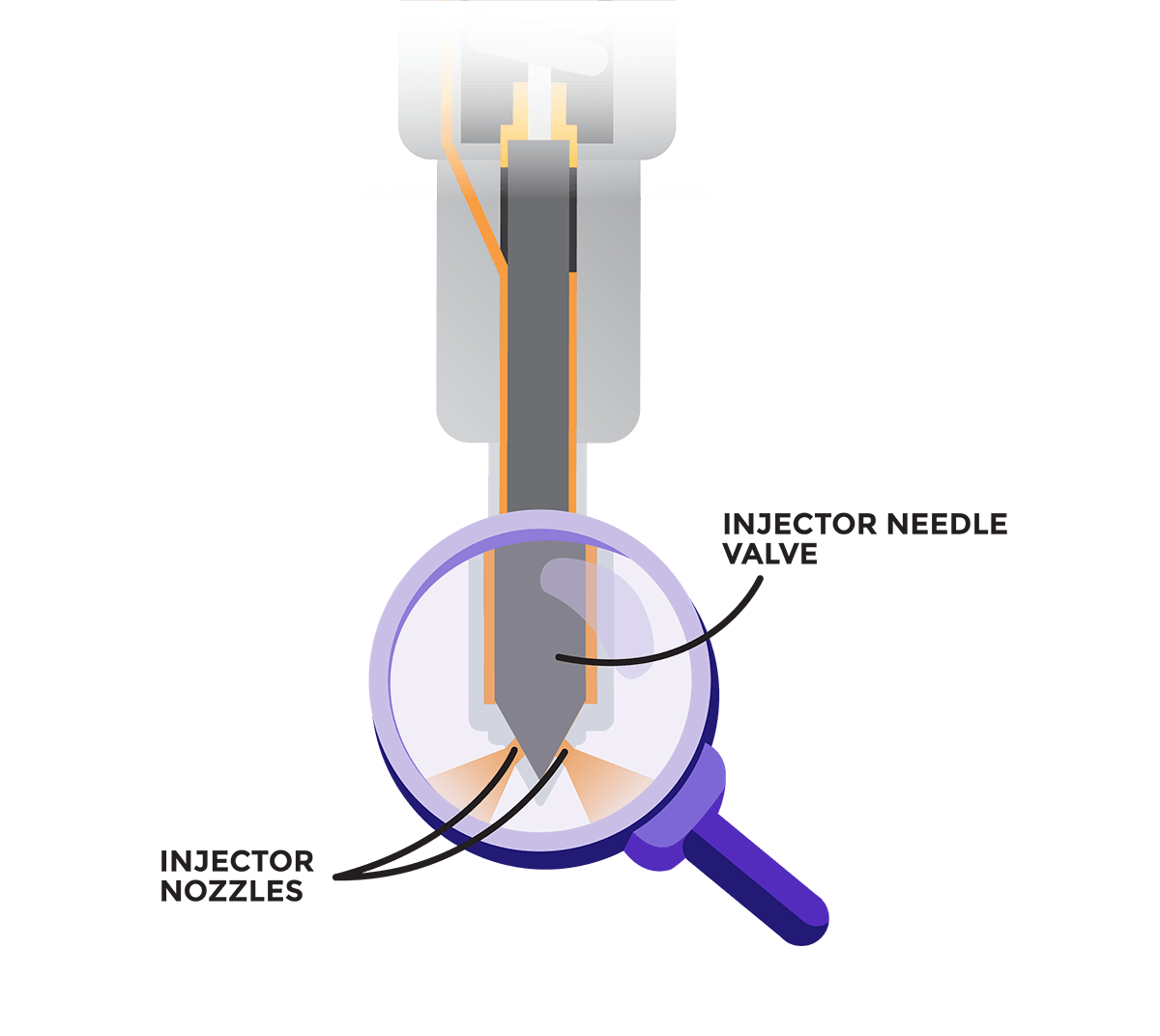

Within a high-pressure common rail fuel injector, there are three main components that are harmed the most by the effects of diesel fuel contamination. These are:

- Fuel injector nozzle holes

- Needle valve and seat

- Electronic Piezo or solenoid-controlled valve

Fuel Injector Nozzle

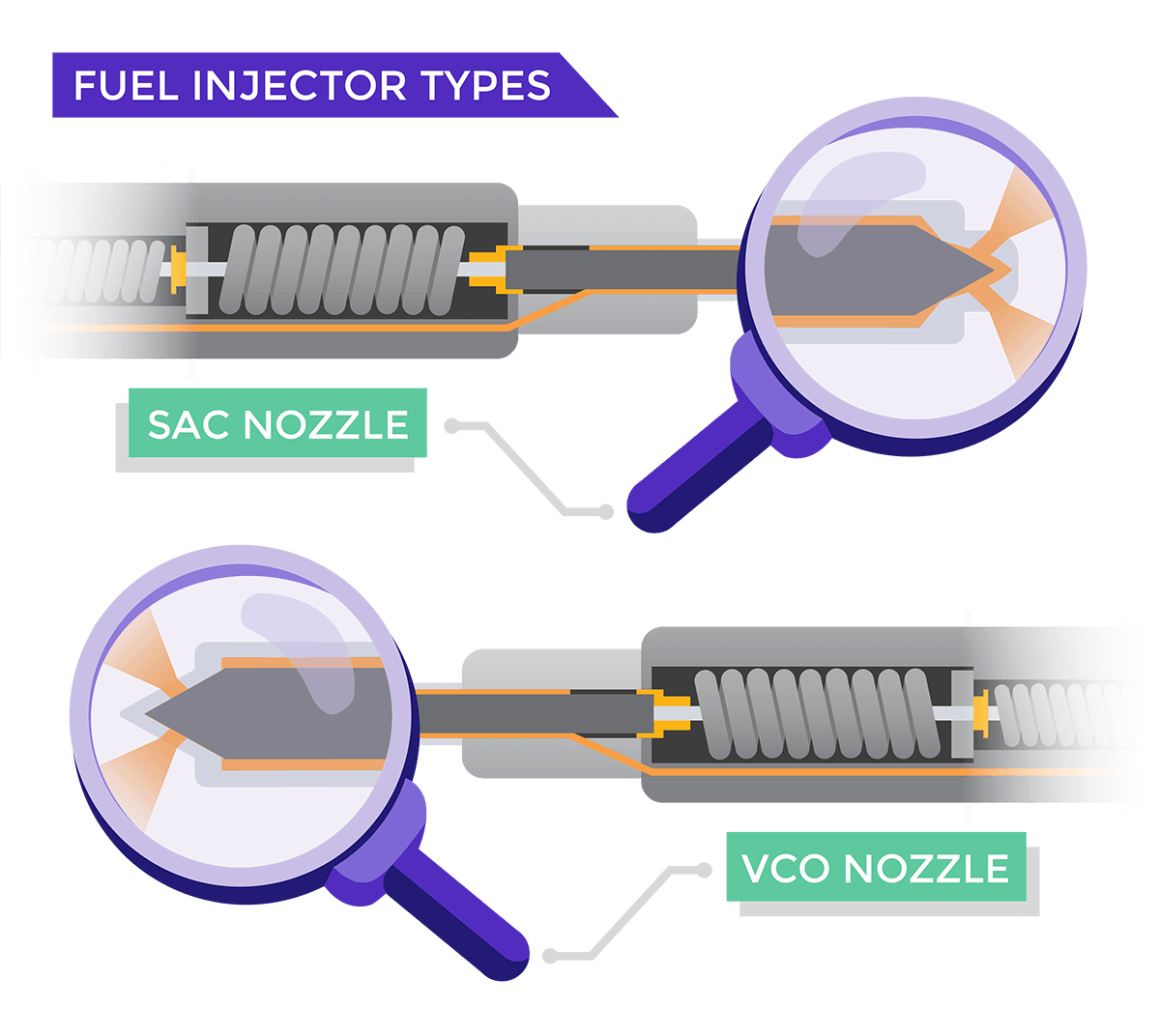

Fuel injector nozzles are designed to spray a mist of fuel into the cylinder for piston compression and fuel combustion. These fuel nozzles primarily come in two designs: the SAC (area around pintel tip) nozzle and the VCO (valve-covered orifice) nozzle.

High-pressure common-rail (HPCR) injectors primarily use the VCO type. This design allows the injector to quickly and totally shut off the fuel as the injection completes. This allows for increased control of the fuel injection as it is critical in HPCR injectors.

This design enables the injector to abruptly and completely shut off the fuel at the end of an injection event, thus providing a more stringent control of the fuel injection event. The two designs can be seen below.

The VCO injection needle valves are known for having particularly fine tolerances and are extremely sensitive to partial failure during the rise and fall actions.

The rise and fall injection actions can occur dozens of times every second in a diesel engine. That is why injector tolerances are critically important in maintaining reliable operation and avoiding partial failures in the fuel injection function.

Typically, fuel injector nozzle holes are susceptible to two circumstances that can lead to injector failure. These two circumstances are blockages and erosions.

The precision involved in the operation of HPCR fuel injectors, although impressive, makes for sensitive components that require specific circumstances for combustion to take place as intended.

When achieved as designed, the fuel mist that is injected into the combustion chamber is burned out before the fuel droplets reach the lining of the engine cylinder. This ensures that the fuel combustion does not damage the cylinder, something that is especially critical for the fuel injection systems to function as intended.

When fuel is unable to complete combustion as it should, soot builds up within the engine and harmful exhaust emissions such as Nitrogen Oxide, Carbon Monoxide, and Particulate Matter are created.

HPCR fuel injectors ordinarily have 5-8 holes that are machined into the injector tip which allow for fuel to be injected into the combustion chamber and achieve atomization.

When the fuel injection action occurs, diesel fuel is sprayed into the combustion chamber. During the power stroke, the piston moves downward and pulls injector fuel spray deeper into the combustion chamber.

When injector tolerances have been compromised, fuel droplets from the injector nozzle may not be able to achieve complete combustion, often resulting in smoke and soot emissions. If the issue is not addressed, soot will build on the injector tips and eventually cause blockages. These blockages can also occur within the engine valves, cylinder walls, and exhaust system.

When injector nozzle holes are blocked due to this build-up, fuel velocity through the open nozzle holes increases due to more fuel being forced to exit the injector through the remaining unobstructed holes.

Blockages in the injector nozzle result in ineffective atomization which contributes to engine inefficiencies and harmful emissions.

When these partial functional failures within the injector occur, it is perceived as best practice to use diesel fuel additives that are chemically designed to clean soot build-up from the fuel injectors.

Although the use of these additives can help, these additives do not rectify the true underlying issues that contribute to injector blockages. Contaminated fuel will still wear down injectors and the fuel additive solution may only act as a bandage for a more serious issue.

Fuel Injector Needle & Control Valve

There are two commonly used fuel injectors in modern engines, electronically controlled unit injectors (EUI) and high-pressure common rail injectors (HPCR). The needle valve in both of these fuel injection types is engineered to stop the fuel from running through the injector tip after the fuel injection action.

When a needle valve fails to properly seal, fuel will drip down into the engine cylinder and onto the piston(s). This dripping fuel can be the catalyst for severe engine problems and catastrophic failures.

In HPCR injection systems, the fuel injectors are continuously under sustained pressure while the engine is running. This leads to a higher likelihood of harm if a fuel injector’s needle valve fails.

Both types of electronic fuel injectors have a control valve that functions to manage the timing of fuel injection sequences.

The control valves in EUI injectors are controlled by an electronic solenoid. HPCR injectors are controlled with a Piezoelectric actuated valve. These Piezoelectric valves are often seen as the most critical injector component because they enable the injection system to have more control of the distance of valve movement and valve speed.

The Piezoelectric valves are especially sensitive to fuel contamination because it wears and damages the components and compromises the designed injection tolerances.

With prolonged exposure to contaminated fuel, contaminants can build up within the injector and result in lethargic movement of the needle valve. This causes wear on the valve, and eventually leads to partial, if not full, functional failure of the needle component within the fuel injector.

Causes of Fuel Contamination

Particulates in the Fuel

Particulate within diesel fuel is the most common form of contaminants. From microscopic fragments of ferrous metals to dirt and grime that is introduced to the fuel, various contaminants can be to blame for a majority of fuel-related issues.

Following the refinement process, the fuel passes through numerous tankers, trucks, and vessels before it reaches you. Because of this, there are many potential sources of unwanted particulate contamination. Older fuel tanks, particularly those made of black iron, are highly susceptible to rust and corrosion.

Because of corrosion, fuel that was previously clean could be contaminated when introduced to a tank that has rust build-up within. If in a transport tanker or truck, constant vibrations and sloshing could mix the particulates with the fuel to a point where all of the fuel is contaminated.

This fuel can often find its way into other tanks for distribution and bulk storage, where it can then contaminate other tanks or equipment, as well as other fuel that will eventually find its way there.

This cycle evolves into a constant problem for equipment and engine operators, making it difficult to pinpoint the source or cause of contaminated diesel fuels.

Rarely is it known exactly where fuel has been passed through before making it to you, leaving the likelihood of receiving contaminated fuel to chance.

Water Contamination

Water in diesel fuel is one of the most troubling types of contaminants, and also one of the toughest to combat in large bulk fuel tanks.

Since fuel is often kept, transferred, and purchased out-of-sight, contamination and build-up of water in diesel fuel can be extremely difficult to spot, unless it is properly tested for.

Not only this, but engine damage from water contamination in fuel can be very costly.

Water can enter the fuel in a number of different ways.

Diesel fuel is a hygroscopic fluid, meaning that it is able to absorb moisture from the air around it. This can become a problem in fuel tanks where full capacity is not maintained for extended periods of time.

By allowing the fuel in a storage tank to have more air overhead to pull water from, emulsified water can develop and become mixed with the fuel in suspension.

Combined with water from condensation, this results in an unfavorable ratio of fuel to water, which can result in contaminated fuel being introduced into the engine or equipment it is being supplied to.

In some cases, water contamination can cause fuel injector tips to explode, should the water make it through the fuel filter and into the engine.

As a potentially catastrophic contaminant, excessive levels of water in fuel can reduce engine performance because of the reduction of energy available within the fuel.

Not only this, but water in fuel can increase the temperature the fuel will freeze at within engine components. This can be especially problematic in cold climates where fuel gelling is already a concern.

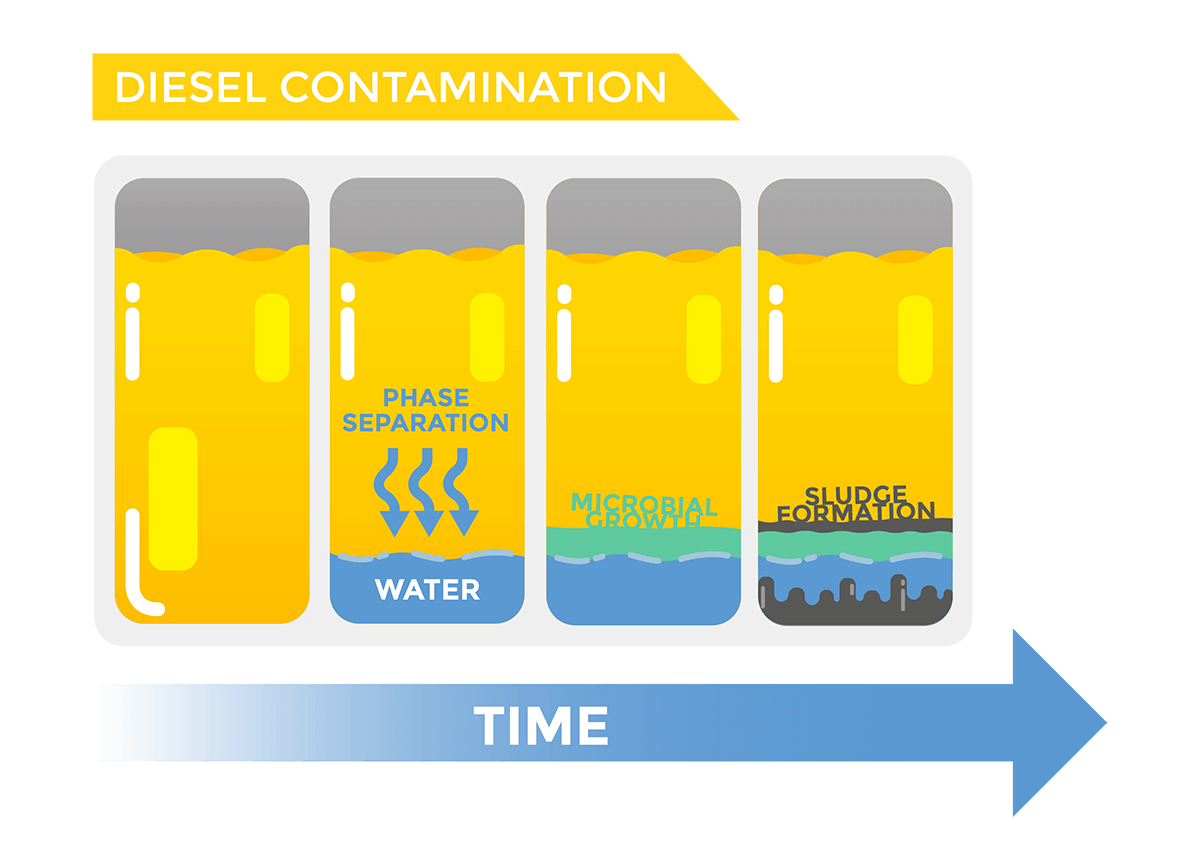

Another type of water contaminant is free water. Free water develops as a layer beneath stored fuel after phase separation occurs.

With the presence of free water in a fuel storage tank comes the possible proliferation of microbial growth within the fuel.

When the presence of free water is ignored, microbial proliferation will occur in the layer where the water meets the fuel. Hydrocarbons in fuel provide food and energy for the “diesel bug” (that is often referred to as “algae”) to rapidly spread.

Once microbial growth exists in a fuel tank, sludge develops as a waste byproduct of the hydrocarbons being consumed by the microbes.

To learn more about the diesel bug and possible solutions: check out our article on Addressing Algae In Diesel Fuel.

Fuel Degradation

Fuel indeed “goes bad” over extended periods of time in storage.

Many people aren’t aware that diesel fuel has a shelf life, however fuel stability is important to the mechanical operability of your engine.

Good fuel samples are typically bright in color and clear. Degrading fuel samples can often be determined visually, with fuel turning dark and murky because of the development of tar and asphaltenes within the fuel.

High sulfur diesel shelf life recommendations are less than a year, while ULSD and biodiesel blends have an even further reduced long-term stability.

When fuel loses stability during degradation, the gums and waxes that develop can contribute to corrosion and damaging deposits on engine components.

Many automotive mechanics will first flush fuel lines and replace the fuel if a troubled vehicle was known to be sitting for even a few months.

With most engines designed to be in frequent use, such as fleet vehicles, fuel stability isn’t something most consumers have at the top of mind.

If you have fuel that is going to be sitting for extended periods of time, such as bulk fuel storage for a fleet or on-site fuel storage for backup generators, equipment managers should be aware of fuel stability timelines.

Diesel fuel composition can begin to change within a month of sitting in storage, with recommended maximum storage timelines without significant degradation of six months to one year.

However, these recommendations are contingent on the fuel being purchased from suppliers and stored in tanks with the appropriate cleanliness and quality standards.

To properly store fuel (especially in large amounts) for extended periods of time, fuel should be polished to maintain optimum fuel quality that is ready for use at any moment.

How to Test for Fuel Contamination

Fuel Testing Tools

To be proactive and catch fuel contamination early, fuel should be sampled and tested from a bulk fuel storage tank at least once every six months. Testing for different contaminants can be achieved in a number of ways, here are the most common tools for fuel sampling and testing:

- Fluid Sampling Pumps

- Fuel Tank Samplers

- Kolor Kut Water Finding Paste

- FUELSTAT ® PLUS

- Liqui-Cult Microbial Test Kits

Proper Fuel Sampling & Testing

Fluid sampling pumps are often used to obtain fluid samples from hard-to-reach spots using flexible tubing. This allows for fluids to be drawn without the worry of cross-contamination, as the fluid never comes into contact with the pump.

Fuel tank samplers, also known as “bacon bombs”, are industrial-strength stainless steel devices used to remove liquid samples from a bulk fuel storage tank. The device is lowered into a fuel tank until the sampler’s plunger makes contact with the bottom of the tank.

The plunger then opens, which admits a sample into the unit. To sample from any desired level in the tank, the plunger can be actuated by a pull-chain attached to the device.

Once fluid samples are obtained, they must be sent to a lab for testing. Getting results from the lab could take days, up to waiting periods of weeks.

For quicker results, Kolor Kut ® Water Finding Paste is a product used to instantly report if there is a presence of water in petroleum fluids such as gasoline, kerosene, diesel, and heavy fuel oil. The paste is applied to a rod and dipped into the tank, with the color of the paste changing instantly upon contact with water.

FUELSTAT ® PLUS is a simple fuel testing kit that provides results in less than 10 minutes. The objective of the test is to provide rapid screening of fuel samples to give a quick and accurate assessment of H. Res., bacteria & other fungi within the fuel.

Liqui-Cult Microbial Test Kits accurately detects and quantifies bacterial and fungal growth in a variety of fluids. Liqui-Cult tests for microbial growth in fuel samples over a period of a few days.

Through frequent fuel testing, the presence of contamination can be determined and action plans can begin to be determined. Depending on the scope of contamination levels and volume of fuel contaminated, some solutions may be more practical to implement than others.

Solutions to Fuel Contamination

What is Fuel Polishing?

Fuel polishing is a fuel filtration technique used across many industries to increase and maintain fuel quality in stored fuel. Through these fuel filtration systems, various forms of contamination are removed and prevented.

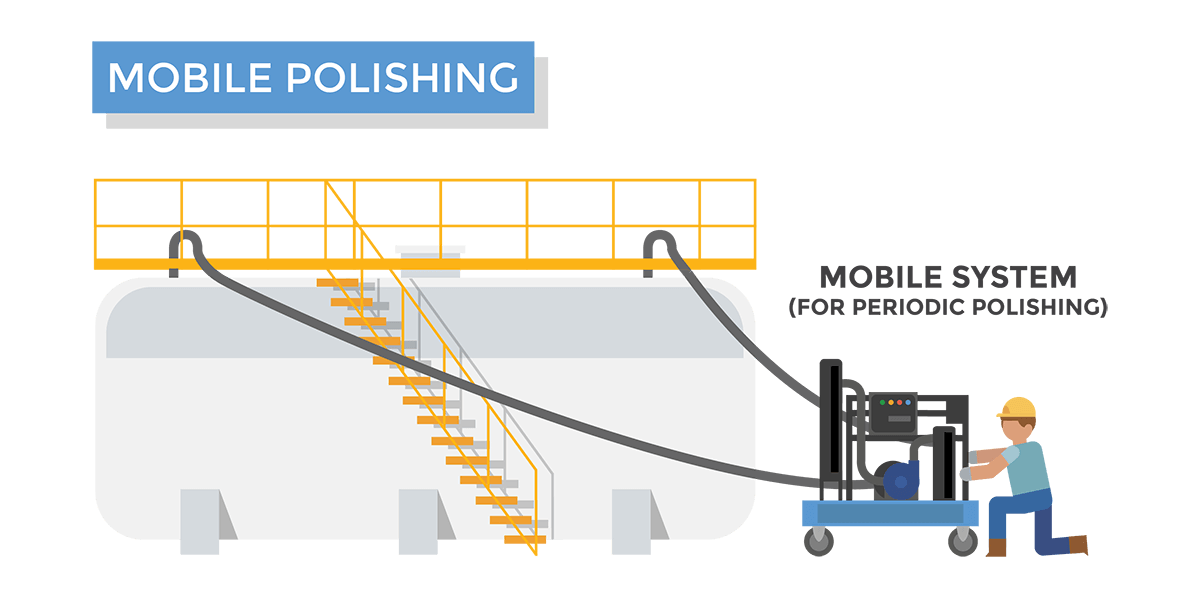

Mobile Fuel Polishing

These polishing systems can be mobile units built onto carts or skids, or these systems can be mounted (sometimes in an enclosure) that is plumbed into the bulk fuel storage tank.

The mobile polishing systems are advantageous when having to maintain a number of different fuel tanks without having to incur the financial cost of installing multiple fixed systems. Mobile systems come in a number of different sizes and flow rates, and we recommend you visit our Mobile Fuel Polishing page to view the different systems that are available.

Mobile fuel polishing may seem like the perfect solution especially if you have multiple tanks, however that is not always the case.

As these units are not fixed onto the fuel storage tank, these systems must be hauled out on a scheduled basis to maintain fuel cleanliness. The problem arises not when fuel is cleaned to the desired fuel cleanliness standard, but rather when fuel is again left to sit untreated.

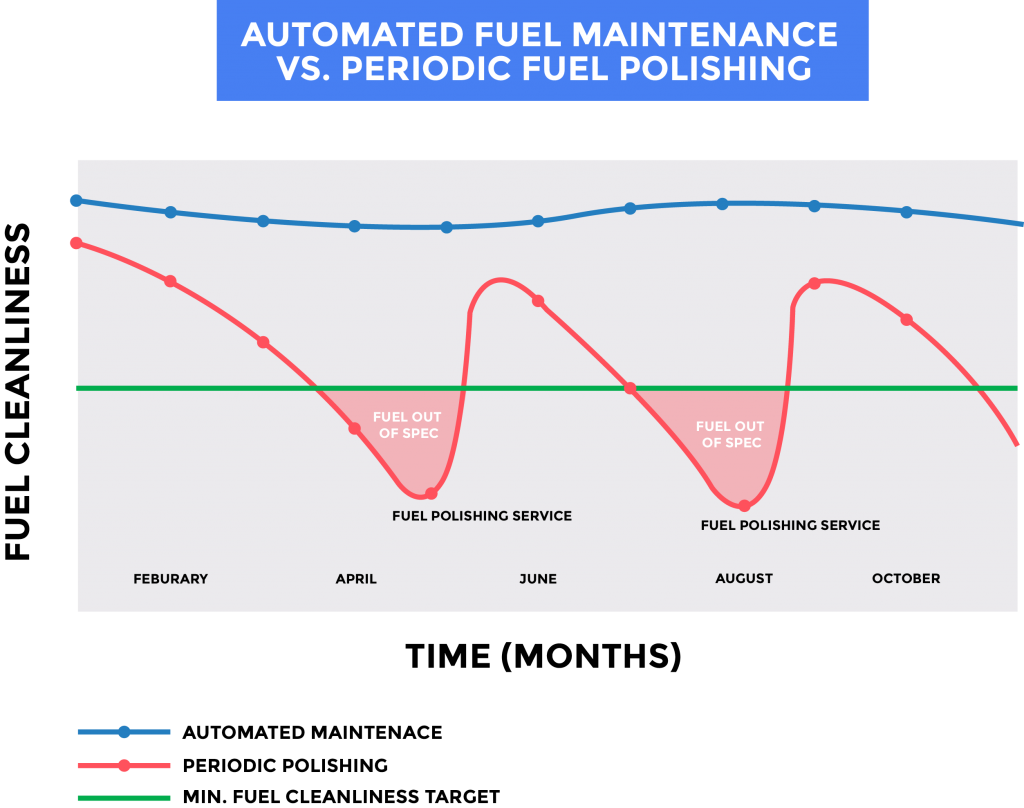

This causes the fuel to fall back out of the desired cleanliness specifications where it must be polished again. This creates a cycle, which is illustrated below, that gives chance that the fuel fails to maintain the quality requirements if stringent polishing cycles are not maintained.

Now, you can see where this fuel polishing cycle could turn into something that proves to be quite taxing, especially in situations where multiple fuel tanks on a specific site need to be treated on a regular basis.

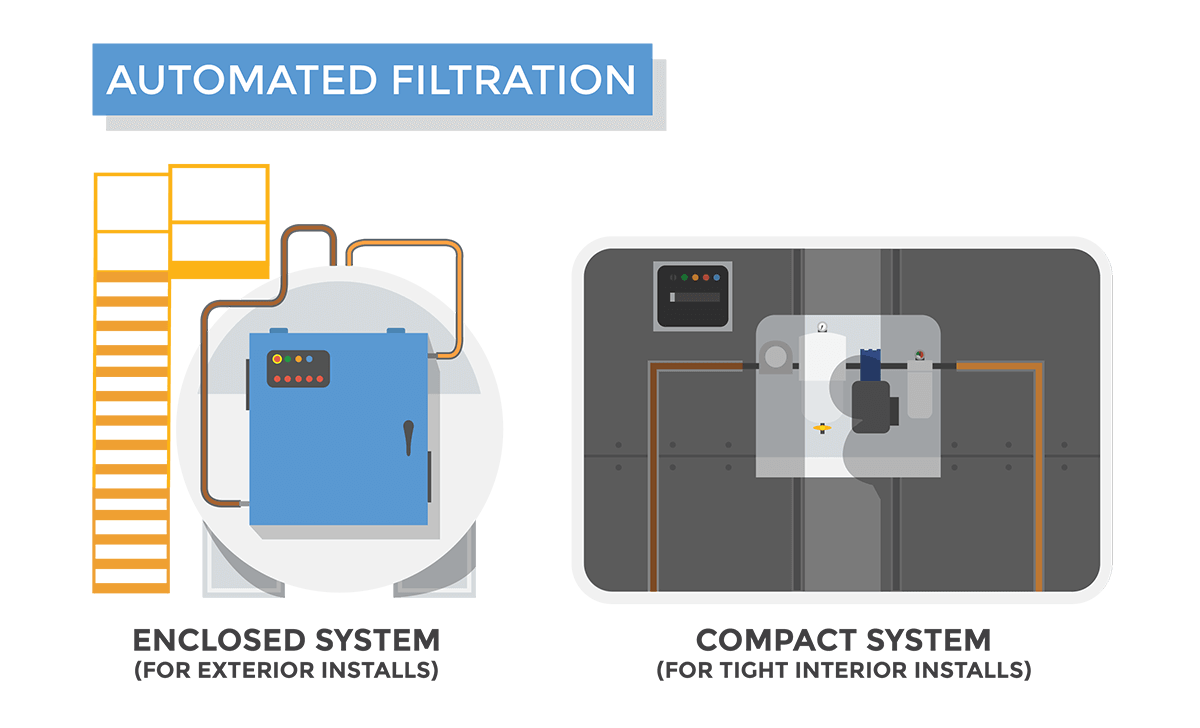

Automated Fuel Polishing

Automated fuel polishing systems can be beneficial to fuel storage in facilities where frequent access for mobile polishing isn’t preferred or practical.

Our Automated Fuel Maintenance and Enclosed Fuel Maintenance systems are engineered to allow for the scheduling of periodic fuel polishing so that fuel is constantly being cycled and polished. This eliminates the concern for fuel to fall out of the desired fuel cleanliness and quality standard.

For facilities that are reliant on backup power systems, this is immensely important. Mission-critical facilities, such as hospitals and data centers, cannot risk electrical downtime in the event of a power outage.

With these facilities having large volumes of stored fuel to power the backup generators, it is important that fuel quality is maintained to ensure quality fuel is delivered to the backup power system at a moment’s notice. Any fuel quality issues could render the backup generator inoperable, putting critical systems at risk.

Levels of Fuel Filtration

Fuel polishing systems have a number of components necessary to ensure that fuel is being cleaned and contamination is removed in an appropriate manner.

Micron filtration removes clumps of fuel and other particulate that could harm equipment. By passing fuel through micron filters, contaminants such as dirt, grime, and sludge can be caught by the filter and removed from the fuel.

With water separation, free water is captured and removed from the fuel to prevent the proliferation of microbial growth. By capturing the water, fuel polishing systems effectively remove the conditions to which “the diesel bug” thrive.

Not only that, but by removing the water from the fuel it keeps the engine and fuel injection system from receiving water that could pose harm to the integrity of the equipment.

AXI International’s LG-X Inline Magnetic Fuel Conditioners are a proprietary part of our fuel polishing systems that use a magnetic field to achieve a number of things.

Through running fuel through the magnetic chamber, metallic particles and fragments are captured and thus prevented from making their way into critical engine components. These metals could be comprised of various ferrous metals or even rust.

Rust is typically a sign of the presence of water within a fuel tank. Rust can only develop where there is water, and if fuel was previously clean but rust was found during the polishing cycle of a fuel tank, chances are that there is water present as well.

The magnetic field is also responsible for breaking down clumps of diesel fuel known as agglomeration where the fuel molecules in diesel fuel, over time, naturally pull together creating thick clumps of fuel. By passing these clumps through a magnetic field, the intermolecular bonds are weakened, allowing clusters to fall apart and return to a more fluid-like state.

Fuel Additives

Fuel additives can also prove to be beneficial for those concerned with fuel contamination issues. However, with such a wide variety available on the market, it could be hard to decide which additive is best suited for your unique needs.

Fuel stabilizers as a fuel additive work in a manner that prolongs the stability of fuel in storage. These fuel stabilizers are often used in circumstances where fuel is expected to sit for an extended period of time without any fuel maintenance.

By dosing the fuel tank appropriately, this fuel additive prevents fuel from oxidizing and experiencing a chemical breakdown.

Combustion catalysts can be used to not only enhance engine performance, but also provide for a more complete burn of fuel being supplied to the combusting cylinder, which results in reduced carbon deposits. This, in turn, reduces engine emissions as less unburnt fuel is released from the exhaust system.

By increasing power output, combustion catalysts can often result in a healthier engine response.

Corrosion inhibitors in certain fuel additives prevent corrosion on metal surfaces, which prolong engine life and equipment operability. This reduces the amount of “surprise” equipment maintenance that is needed due to the failure of certain parts within an engine’s mechanical system.

The corrosion inhibitor is comprised of compounds that attach to component surfaces and form a film that acts as a lubricant which reduces engine wear and extends the lifetime of mechanical components.

We recommend AFC Fuel Additives as the go-to fuel additive to add to your fuel maintenance schedule. As the only fuel additive offering all of these features and benefits within a single formula, AFC Fuel Additive is the smart choice for your equipment. With a concentrated formula, just eight ounces of AFC Fuel Additive is able to treat 320 gallons of fuel. AFC is also available in 1 Gallon (treats 5,000 gallons), 5 Gallon (treats 25,000 gallons), and 55 Gallon (treats 275,000 gallons) quantities.

Summary

Through gaining an understanding of what diesel fuel contamination is, what causes it, how to test for it, and how to treat and prevent it, we hope to give you greater in-depth knowledge on just how critical your fuel quality is.

From lawnmowers to tractor trailers, fuel quality is something that affects everyone logistically- for it could be the reasons behind your car not running and your generator failing. Sometimes, the application is small, and fuel is simply replaced before damage is done and you are on your way again.

But, in many cases, this can be a costly solution especially when there are thousands of gallons of fuel at risk. And in the worst-case scenario, this fuel can not only be contaminated, but also further contaminate and cause detrimental mechanical issues within the equipment the fuel was being supplied to.

Engines and equipment rely on quality fuel to operate as designed, and when that standard of fuel isn’t being supplied (which is often the case), gradual wear and breakdown of components could lead to costly repairs, particularly in and around the fuel injection system.

To ensure fuel quality and mitigate the effects of contamination, it is recommended to instill fuel maintenance systems and procedures. At the general consumer level, this could mean using a fuel additive when you fuel up your vehicle. At the business operational level, this could mean installing automated fuel management systems to polish bulk fuel and prevent contamination from proliferating.

Fuel Filtration

Fuel Management

Stay Up to Date

Engineering Services

Products

Resource Center

Information

Copyright © 2024 AXI International | All Rights Reserved.