Ultra Low Sulfur Diesel (ULSD): the Good, the Bad, and the Rusty

You have probably heard mixed reviews about Ultra Low Sulfur Diesel (ULSD). Some say it is great for the environment while others claim it causes more problems than it solves. If you are looking for an unbiased take on the ins and outs of ultra-low sulfur diesel, you are in the right place.

Below we cover why ultra-low sulfur diesel exists, its benefits and disadvantages vs. traditional diesel, and what you can do to protect your vehicle or equipment from any negative side-effects of ULSD.

Why Does Ultra Low Sulfur Diesel Exist?

In a nutshell, Ultra Low Sulfur Diesel (ULSD) was created in response to a number of regulatory actions aimed at reducing diesel fuel emissions.

Clean Air Act Amendment (1990):

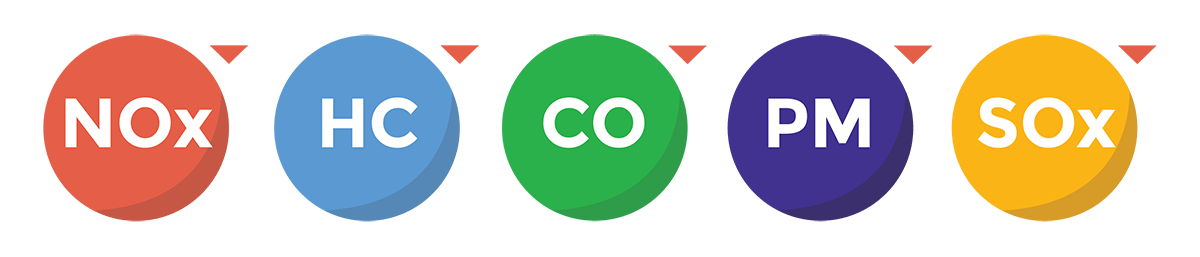

In 1970, Congress passed the Clean Air Act as a means to reduce harmful emissions from automobiles. The Clean Air Act was later amended in 1990, requiring stricter emission reductions of hydrocarbons, carbon monoxide, nitrogen oxides, and particulate matter.

Concurrently, the EPA started imposing sulfur content limits on diesel fuel in an effort to help buses and trucks become compliant with other emission standards coming into effect that year.

The primary motivator for reducing overall emissions was to mitigate the harmful health and environmental effects caused by fossil fuel emissions.

Highway Diesel Program (2001):

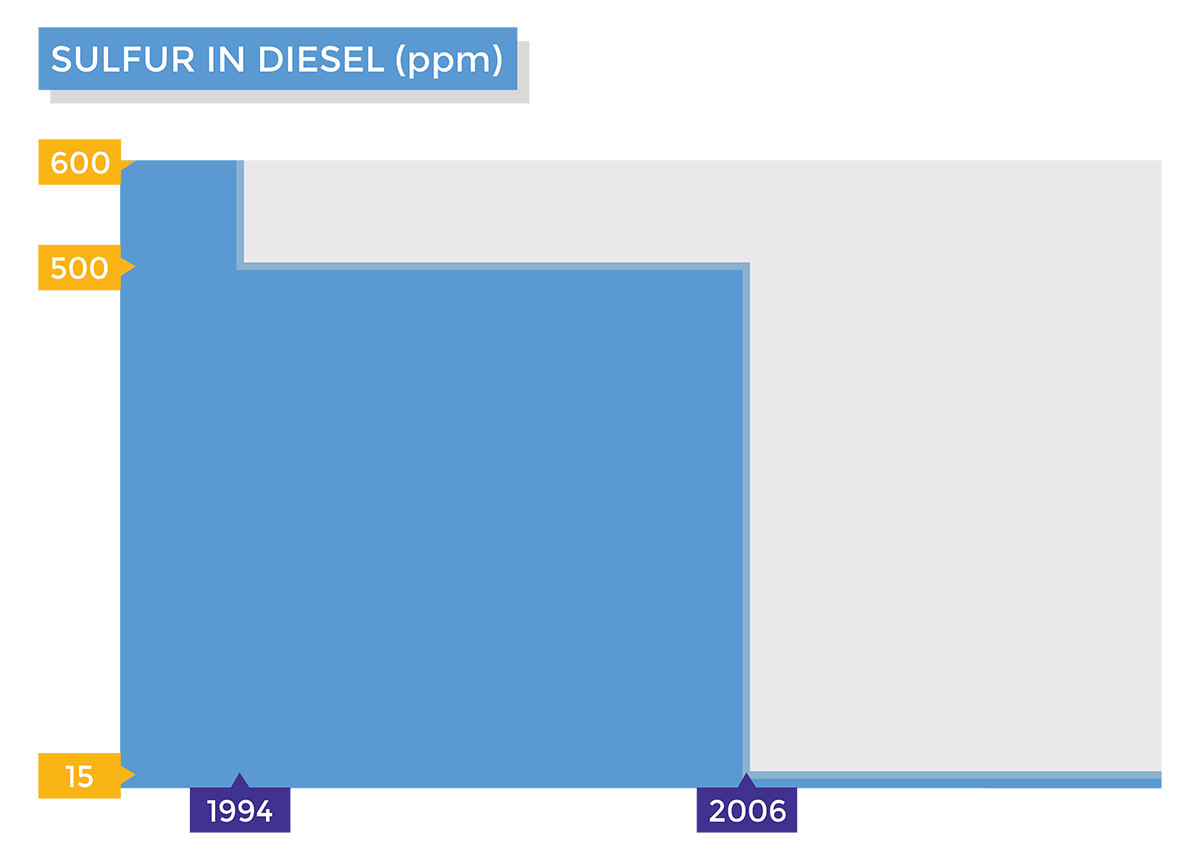

In 2001, the EPA finalized a federally mandated program called the 2007 Heavy-Duty Highway Diesel Program. This program was established to further decrease emissions by enabling the use of advanced emission control technologies for new highway diesel engines. Although effective, these technologies were found to be easily damaged by sulfur, requiring serious sulfur reductions in diesel fuel in order for them to be used. Effective June 2006, the maximum sulfur limit in diesel was slashed from 500 to 15 parts per million (ppm).

This reduction officially marked the switch from low sulfur diesel (500 ppm) to ultra-low sulfur diesel (15 ppm).

Clean Air Off-Road Diesel Rule (2004):

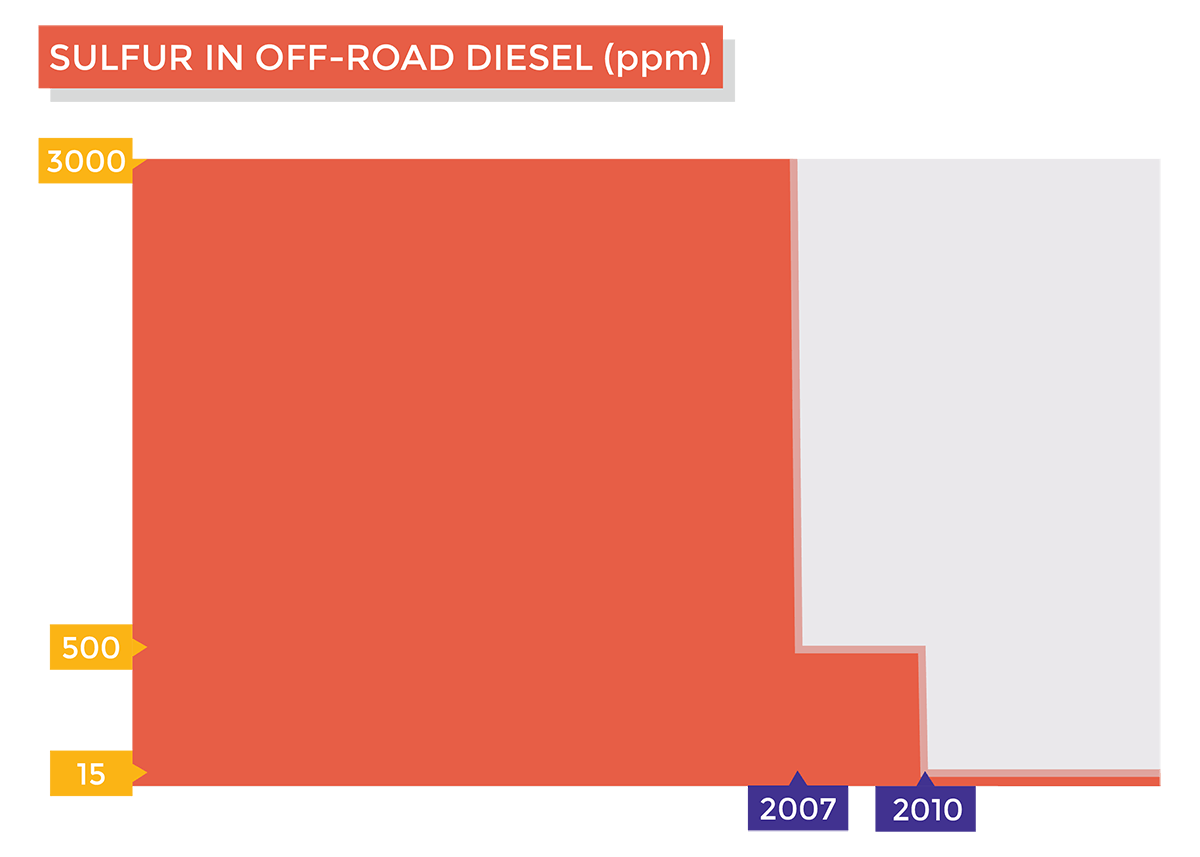

Shortly after the highway diesel program’s inception, the EPA issued the Clean Air Non-Road Diesel – Tier 4 Final Rule. This rule mandated sulfur reductions for off-road diesel engines, effective 2007.

As a result, the maximum sulfur limit in off-road diesel fuel dropped from 3,000 to 500 ppm in 2007 and later 500 to 15 ppm in 2010.

The Pros & Cons of Ultra Low Sulfur Diesel

The intended effect of lowering sulfur content in diesel fuel has led to many positives that can be derived from the large reductions in harmful emissions. Unfortunately, to achieve reduced sulfur levels, the fuel must first be processed. This processing has led to some less than desirable side effects due to the changes it makes to the fuel’s chemistry. Whether the benefit of reducing emissions outweighs the negative side effects of ultra-low sulfur diesel is a judgment we will leave for you to make.

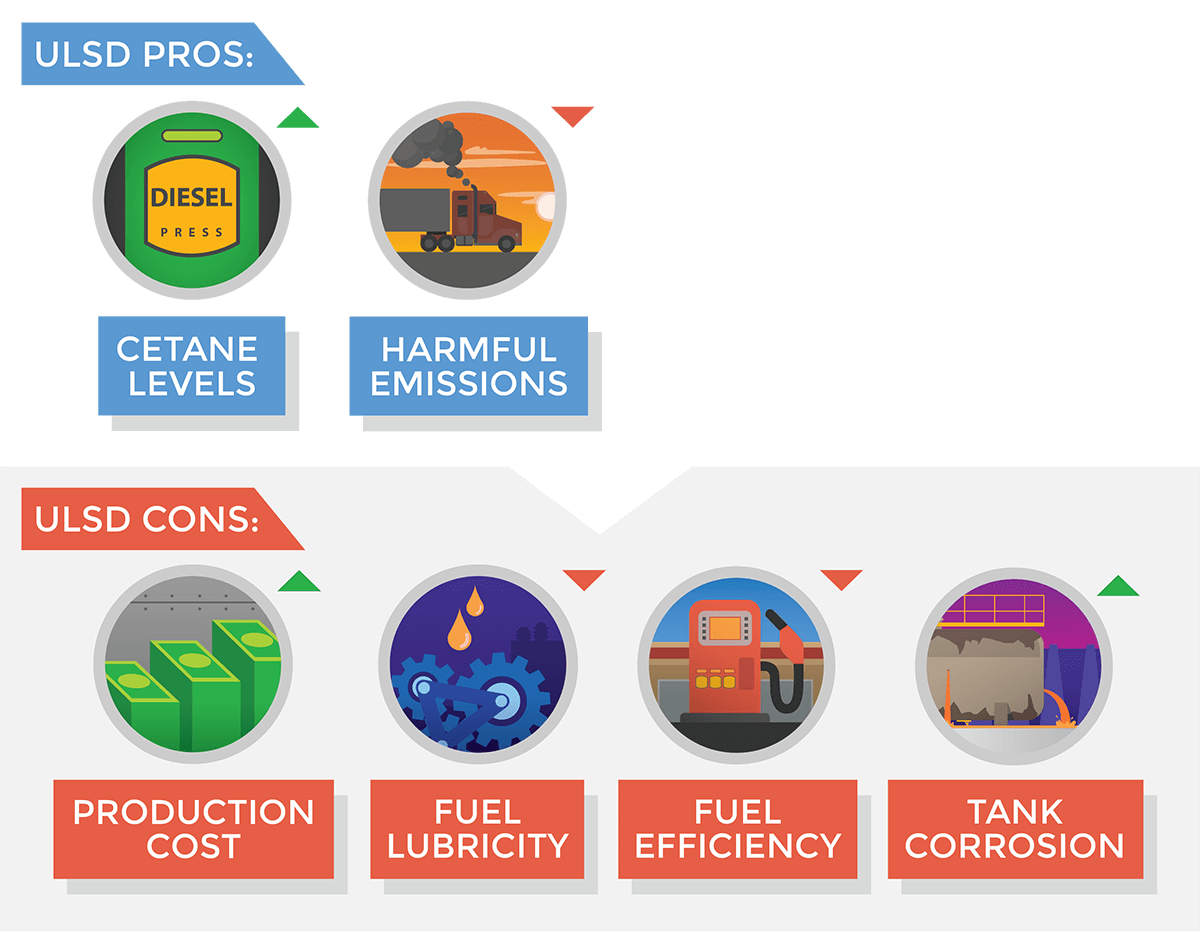

The Good: Emission Reductions

Since the 90s, EPA mandates have resulted in a 99.7% reduction of sulfur content in diesel fuel. This reduction is directly responsible for a decrease in sulfur dioxide (SO2) emissions which, alone, have been a major contributor to serious health and environmental issues.

Health concerns related to sulfur dioxide (SO2) exposure include respiratory problems and lung damage. Tree, plant, and stone damage, acid rain, and haze are some of the environmental effects of sulfur dioxide (SO2) emissions.

Sulfur reduction in diesel fuel has also enabled the use of advanced emission control devices in modern diesel engines. These devices have been able to reduce nitrogen oxide and particulate matter emissions by 90% and 95% respectively. Nitrogen oxide and particulate matter have both been found to contribute to serious health problems such as premature mortality, aggravation of respiratory and cardiovascular disease, aggravation of existing asthma, acute respiratory symptoms, chronic bronchitis, and decreased lung function. In addition to these issues, NOx and particulate matter emissions are suspected to be carcinogenic and contribute to the development of lung cancer.

In 2004, it was estimated that heavy-duty trucks and buses were responsible for about 1/3 of all nitrogen oxide and particulate matter emissions. By reducing emissions from these popular modes of transport, it can become apparently clear that the benefits of ultra-low sulfur diesel lie in the betterment of both public health and the surrounding environment.

The Bad: Changes in Fuel Chemistry

Removing sulfur contents from diesel fuel has been shown to greatly alter the lubricity and overall chemical composition of the fuel. Refineries use severe hydrotreating to remove sulfur. This is a process that also happens to decrease diesel’s natural lubricity, lower energy density (fuel economy), and increases overall production costs.

While hydrotreating does increase the fuel’s cetane level, most of the side effects of hydrotreating are less than desirable. The fuel economy of ultra-low sulfur diesel is estimated to decrease by 1% and, according to the EPA, severe hydrotreating also increases fuel production costs by 5 to 7 cents per gallon. However, these costs may be significantly higher depending on the market, distribution, and other production factors. Lower fuel lubricity is known to contribute to increased engine wear which can also increase maintenance and repair costs for equipment that consume ultra-low sulfur diesel.

The Rusty: Corrosive Effects of ULSD

In 2007, pollution awareness and prevention were on the rise as emission mandates came into full effect. Since then, tank corrosion has hit an all-time high for both gasoline and diesel storage. A recent study suggests this may be symptomatic of fuel tankers participating in switch loading where tanker trucks might transport ethanol-based gasoline one day only to haul ultra-low sulfur diesel the next.

Alone, ultra-low sulfur diesel has a higher affinity to water than traditional diesel. Water is known to be one of the main contributors to tank corrosion while also fostering rapid microbial growth in diesel. It has been shown that mixing ULSD with small amounts of biofuel, such as ethanol, may accelerate tank corrosion. This is due to the microbes in the diesel fuel digesting trace amounts of ethanol, creating high-enough levels of acetic acid to cause significant corrosion of the surrounding tank.

In conclusion, the benefits of ultra-low sulfur diesel are undeniably noble but, as with many significant changes, there will always be trade-offs to consider.

Fortunately, there are a number of products and technologies created to help mitigate the undesirable side effects of ULSD.

Preventing Problems Caused by ULSD

There may be several issues created from the processing of Ultra Low Sulfur Diesel (ULSD) but almost none of them are unable to be addressed through the adoption of new fuel technologies and products.

Addressing Reduced Lubricity & Fuel Economy

As previously mentioned, hydrotreating diesel fuel to remove sulfur does reduce overall lubricity and energy density (fuel economy). To effectively address these problems, one can adopt a fuel additive, possibly addressing both issues with a single bottle. Using a fuel additive does require the individual to regularly dose their fuel supply upon fill-up, but the benefit they receive from doing may exceed that of simply restoring what was lost during the hydrotreating process.

Much like the supplement industry, there is no shortage of fuel additive offerings on the market. Some of these options work quite effectively while others are simply well-marketed “snake oil”. When looking to adopt a fuel additive we strongly encourage you do your own research before putting your hard earn dollars to the test.

AXI International provides a line of broad-spectrum fuel additives, all of which feature a broad set of benefits in addition to increasing fuel lubricity and improving fuel economy. In many cases, it has been shown that our AFC fuel additives have more than paid for themselves with fuel efficiency gains alone. This is mainly achieved with a fuel catalyst which enables a more complete combustion of the fuel, burning more fuel for power in the engine and sending less unburnt fuel out the exhaust. To learn more about our fuel additives click here. If you would like to discuss our additive offerings with one of our experts, fill out the form here.

Preventing Corrosion & Unplanned Downtime

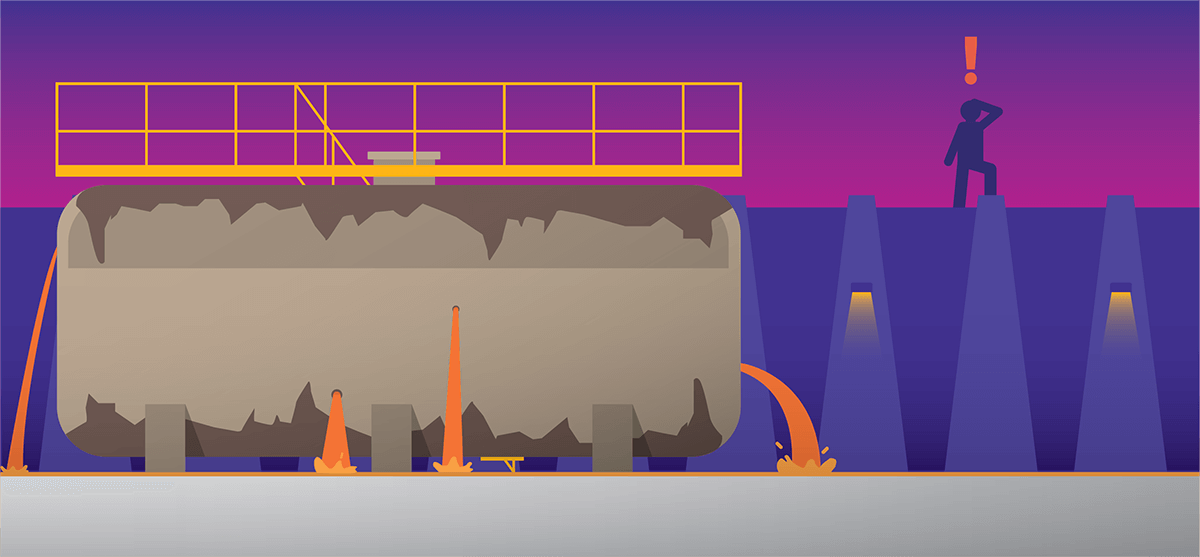

Accelerated tank corrosion is no doubt a serious issue, especially for companies storing large volumes of Ultra Low Sulfur Diesel (ULSD) for backup power applications. ULSD’s high affinity to water and the practice of fuel switching are two factors contributing to this alarming problem. Luckily, there is a solution to this in the form of regular fuel filtration.

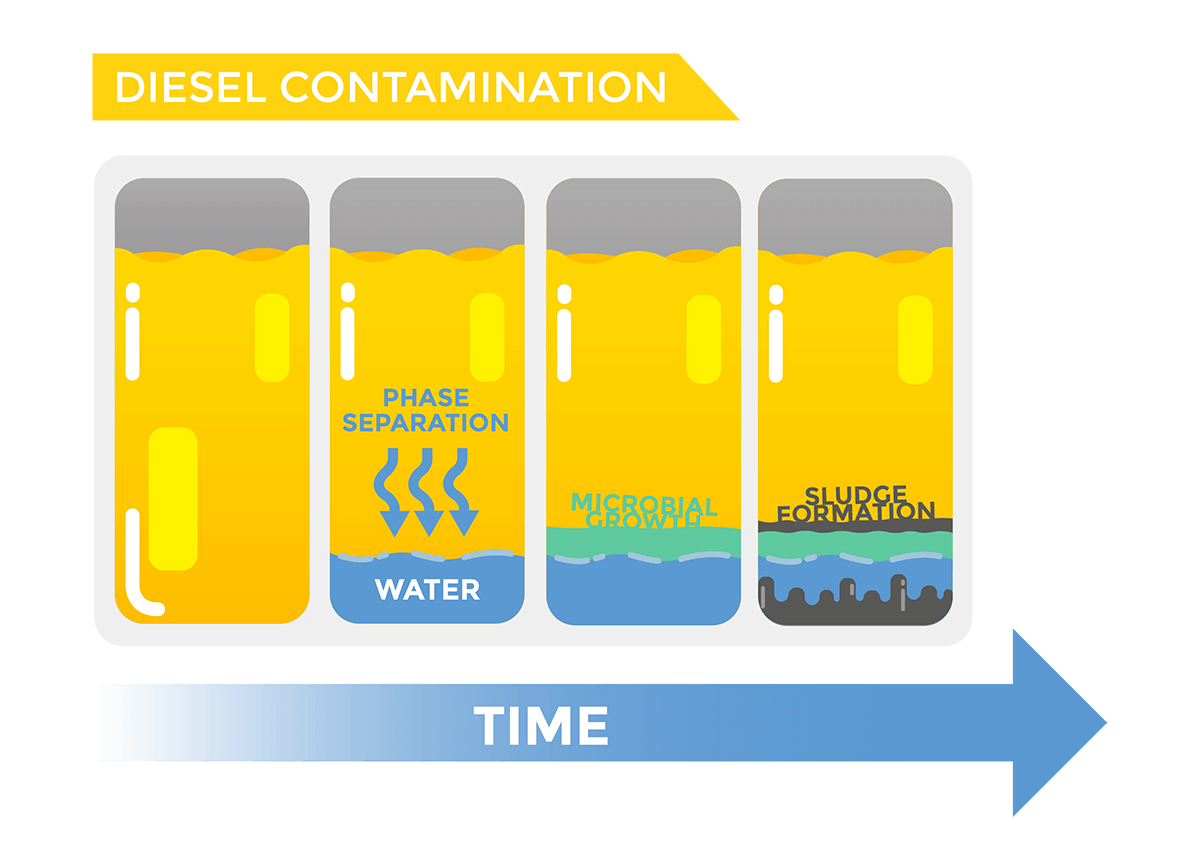

Water in diesel fuel has long been an issue leading to tank corrosion and rampant microbial growth (“the diesel bug”).

When microbes proliferate in the fuel, they begin to produce a sludge byproduct that prematurely clogs onboard filters of connected equipment like backup power generators. The clogging of these filters can lead to unplanned maintenance and downtime, a serious issue for mission-critical facilities. In addition to producing sludge, these microbes will break down trace amounts of biofuels, producing acetic acid. This acid, alongside water, contributes to accelerated tank corrosion.

By regularly filtering water out of the fuel, one can prevent accelerated tank corrosion from occurring. Without water, microbial contamination cannot occur, and without microbial contamination, acetic acid cannot be produced from the trace amounts of biofuel often found in ultra-low sulfur diesel.

So one may ask, how is it that water continually finds its way into the fuel and how do I regularly filter water out of the fuel?

To answer the first question, water is always present in fuel to some degree. This presence is usually higher in ultra-low sulfur diesel and biofuels due to their chemistry. Through tank condensation, water is continually reintroduced into the fuel supply as warm days turn into cooler nights. To answer the second question, you generally have two options to filter contaminants, such as water, out of your fuel supply:

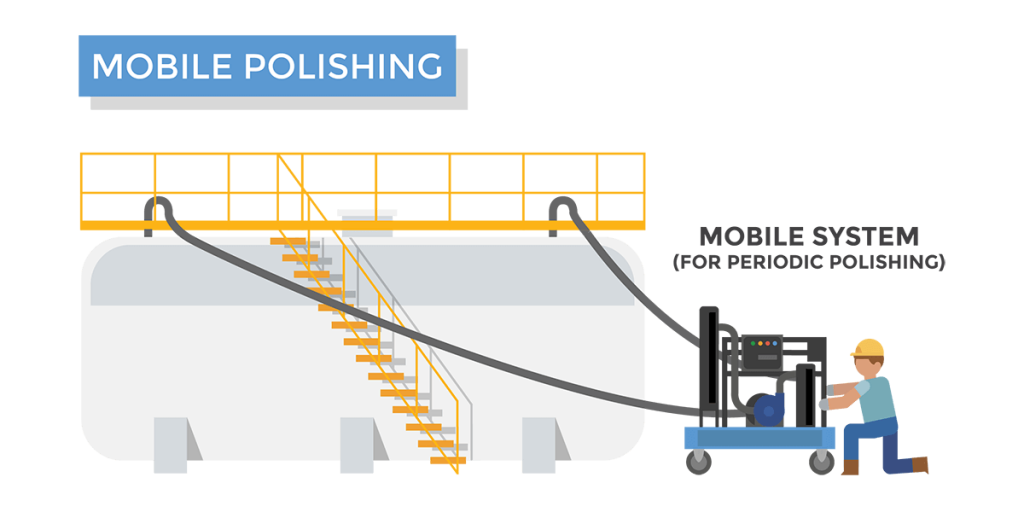

Option #1: Periodic Fuel Polishing

One can purchase a mobile fuel polishing cart or hire a service to bring specialized equipment to filter your fuel supply. This service is usually done in a reactive manner as regular fuel testing is carried out to detect if water or microbial contaminants have reached a certain level to justify the servicing.

Although effective, this option is not recommended for mission-critical and backup power applications due to its reactive nature. A lapse in fuel testing or filtration can easily lead to fuel contamination issues outside of tank corrosion such as sludge and particulate accumulation.

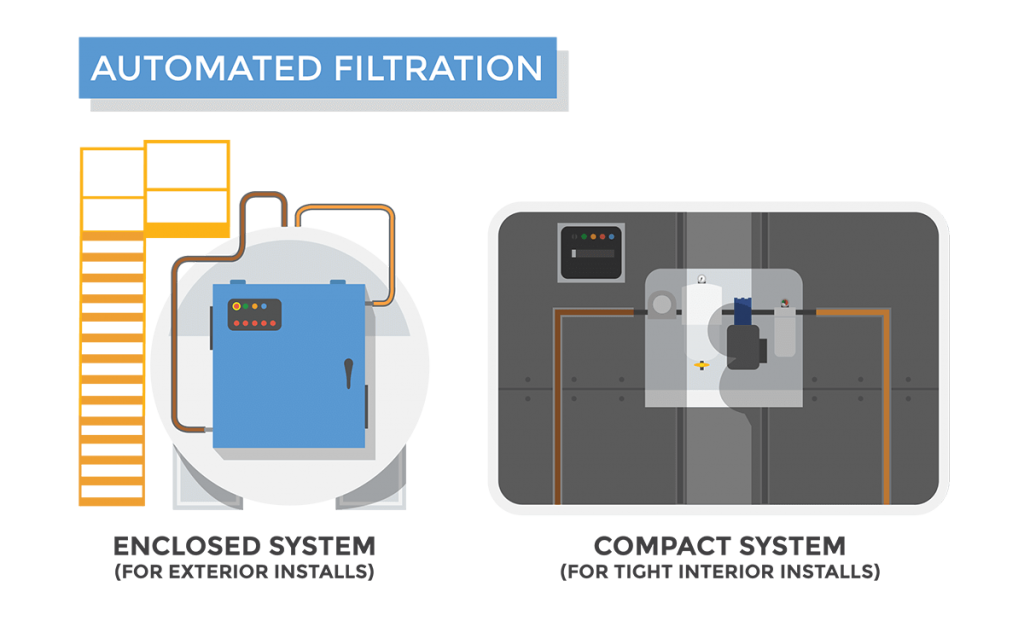

Option #2: Automated Fuel Filtration

One can also purchase and install a fuel maintenance system to automatically filter the attached fuel supply on a scheduled basis.

This option requires minimal involvement outside of periodic filter changes on the installed fuel filtration system. Regular fuel filtration is considered a best practice as it ensures the fuel remains free of water and other damaging contaminants, protecting your tank and the attached equipment from the shortcomings of ultra low sulfur diesel and newer biofuels.

Fuel Filtration

Fuel Management

Stay Up to Date

Engineering Services

Products

Resource Center

Information

Copyright © 2024 AXI International | All Rights Reserved.